Some timber framers use a CNC machine to cut their timbers, some do not, and some offer both hand cut timbers and CNC cut timbers. Offering both would seem to give you the most flexibility, but these machines are quite an investment.

CNC machines are great for simple timber designs with beams that aren’t too large and joinery that isn’t too complex. With a CNC machine, you can provide cut beams in no time compared to hand cutting each joint. They are great for timber frame kit homes.

We do not have a CNC machine in our shop. Many of our frames couldn’t have been run through a CNC machine even if we had one. The beams would have been too large — the joinery too complex — and many designs had some curved pieces or columns or logs.

We are a custom shop and we do custom work!

Nemacolin Woodlands Ski Lodge in Farmington, PA

Take a look at the complex steel joint where the braces connect with the log column. The braces for this frame represent tree branches. It’s a neat idea, and was a pretty big engineering challenge, which we love!

Camp Hayden – Heavy Timber Frame Dining Hall for the Fresh Air Fund

Similar to Nemacolin, The Fresh Air Fund Dining Hall is a complex frame. It has large beams, intricate steel joinery, and finials. It is another example of a project where a CNC machine wouldn’t have been much help.

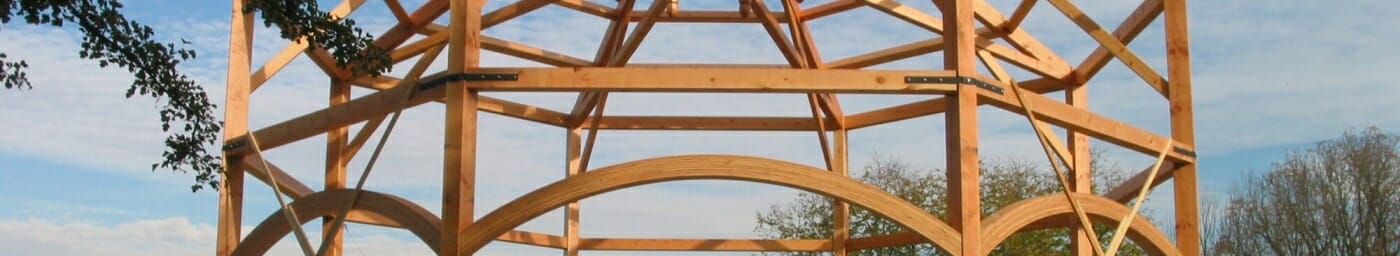

Chapel for Holy Apostle’s – Heavy Timber Frame Octagon Tower

This timber frame chapel has glulam arches — a steel compression ring that is holding the trusses together — and bents that are connected to each other with purlins and steel strapping that surround the exterior of the frame.

We are crafts-men and crafts-women. We like to hand-cut our beams, because hand-cuts offer the most control, allow for more design options, and keep great people doing great work in our shop.

Thank you for stopping by our timber framer’s blog. If you’re interested in a custom timber frame, or have any timber work questions, we invite you to get in contact, ask an expert, or share your thoughts in the comment section below!

Great shot looking up through the cupola, I can see the little tree, so the raising must be complete!

Yes, this is a cool shot. The main octagon is raised by VTW crew and ready for the contractor to finish it up.

You don’t mention Hundegger specifically in the body of your blog post, but since you tagged the post with Hundegger I can only assume you’re talking about our equipment. If you want hang your hat on the fact that you’re “handcrafting” your frames that’s fine, but don’t say you don’t want to use a CNC machine because you imagine it can’t handle the timbers or joinery you’re cutting. You would be surprised what a Hundegger joinery machine can cut these days. For example, our machines can handle up to 18″ x 48″ material.

I am not suggesting that you get one of our machines – you have decided that’s not where you want to go with your business and that’s fine – but don’t try to say it’s due to the limitations of the machine. In fact, I’d appreciate it if you’d remove the Hundegger tag from your blog post. Thanks!

Thanks for you comment Leonard. The tag has been removed. It is great to hear that the capabilities of CNC are improving. I would indeed be very impressed if a CNC machine was capable of efficiently producing the complex joinery that we use on the custom “one off” frames that we do. As I recall, one of the limitations was the depth of the mortises the machine could cut. How deep can you go now? Best regards, Doug Friant