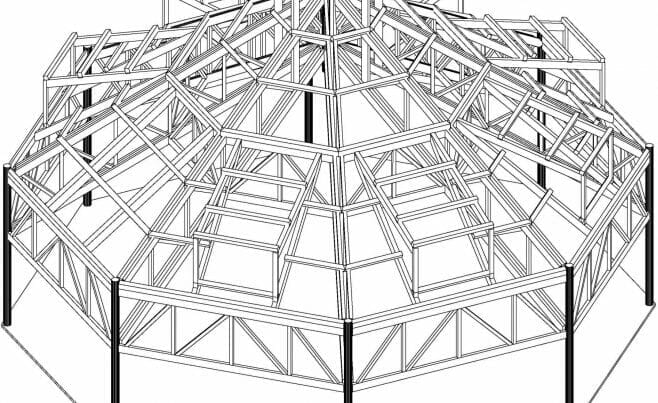

The Spruce Camp lodge is at the base of Stowe Mountain in Stowe, Vermont. It is our largest clear span timber frame to date – an 80 foot octagon!

We worked with Engelberth Construction , BSA Architects, and BVH Engineering on this project. Our in-house engineer did the structural engineering for the frame.

All of our frames are handcrafted to meet exact project requirements, and we enjoy working with our clients to make sure the details – from design to finish – are just right.

If you like this timber frame ski lodge, or have timber work questions, we invite you to get in contact or ask an expert!

Have a Question?EXPLORE THE SKI LODGE

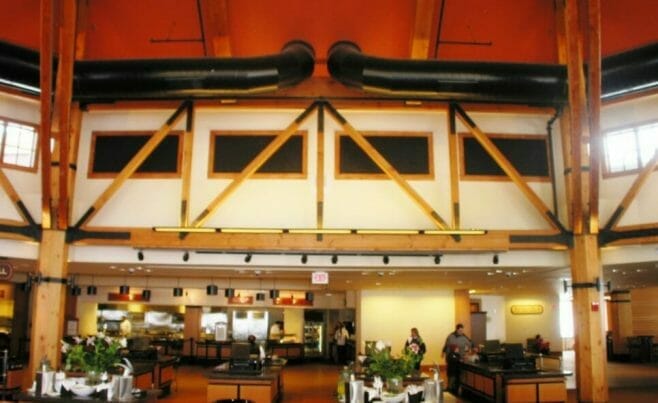

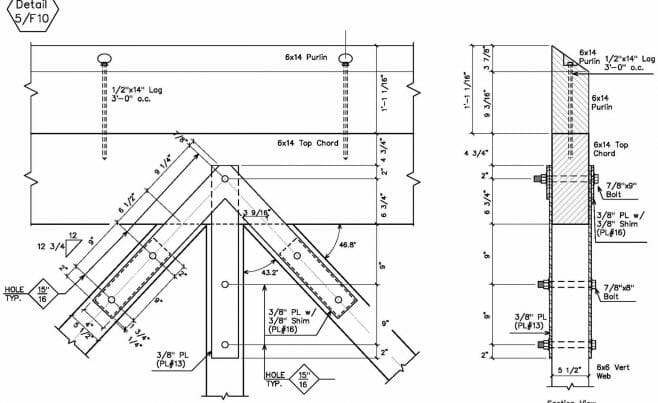

The interior of the frame shows off decisions that were made early in the process, like the truss design, timber species, and joinery style. This base lodge has double chorded girder trusses made of douglas fir. The timber connections are reinforced with steel gusset plates.

SEE THE PROCESS - ASSEMBLY & RAISING

After a timber frame has been fabricated, our crew often travels to the job site to assemble and raise the frame. The same people who cut the frame do the assembly.

SEE THE PROCESS - DRAWING & PLANNING

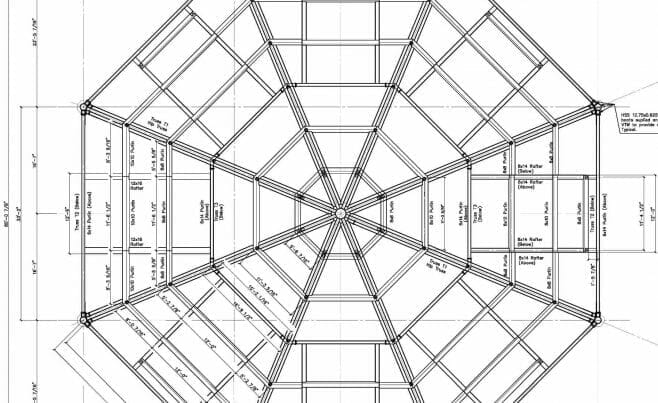

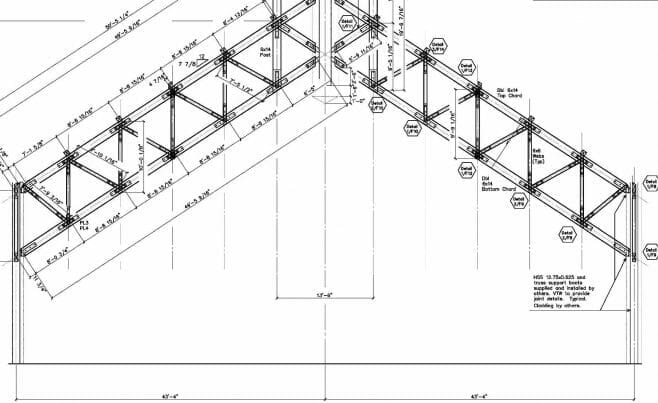

The timber frame design process involves a series of sketches and review with the client and their architect — including a 3D model of the frame — until there is an approved final design. With the final design, detailed 2D shop drawings are created and used to fabricate the frame.