Tools

Hand Crafting Timber Frames

At Vermont Timber Works we still handcraft all of our frames using classic timber framing tools like framing chisels, mortising machines, beam saws, peg drills, slicks and more.

While many other timber framers have started using automated equipment for fabrication, we have found that it is still better, and more accurate, to use hand tools.

For design, we use state of the art computer CAD programs and develop detailed shop drawings. Then we use cutting tools to fabricate each timber individually and precisely.

Scroll down the page to see some of the tools we use to fabricate custom timber frames. Click here to download a list of tools that we bring onsite to raise a timber frame.

The following photos detail the different tools used to handcraft timber frames, from the beginning stages when the timber is still in log form, up to the final steps of using chisels and mallets to cut beam details.

Have a Question?

AT THE SAWMILL

LOGS GOING UP THE CONVEYOR TO THE SAW MILL

We buy our hemlock and pine timbers from local mills in Vermont and New Hampshire and our douglas fir timbers come from Oregon. Timber can also come from California and Canada. In this picture, the bark is being stripped from logs at a sawmill.

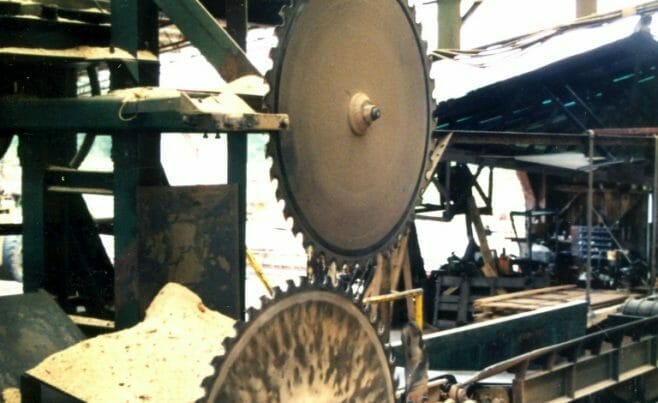

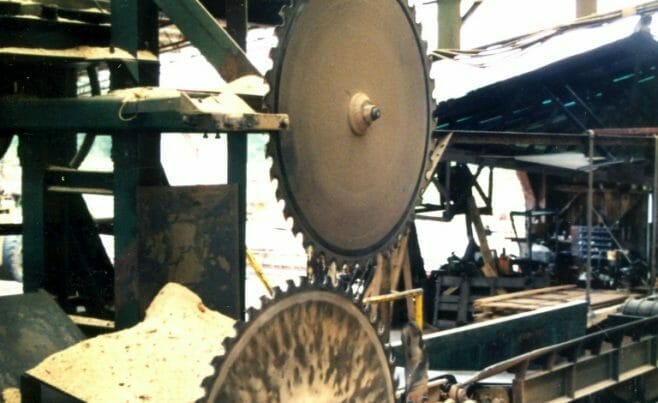

THE SAWS AT THE MILL

After their bark is stripped off, the raw logs are cut into square timbers. After being cut, the saw mill bands the timber together, loads it onto a tractor trailer truck and then ships it to our shop.

WOOD-MIZER PORTABLE SAWMILL

SET UP OF THE PORTABLE WOOD-MIZER

Having a Wood-Mizer Portable Sawmill in the yard comes in handy when we need to re cut a piece of timber after it arrives from the supplier.

CUTTING WITH A WOOD-MIZER

Timber needs to be re cut with the portable sawmill when there's been a change in sizing, or when we're working with reclaimed wood.

THE LAYOUT

LAYING OUT TIMBER IN THE WORKSHOP

The timbers are brought into the shop and laid out by hand using the CAD generated design drawings. Accuracy is assured by a triple checking process. We use traditional measuring tools for the layout, like a framing square, bevel squares, etc. It is the most exact way since every timber is unique.

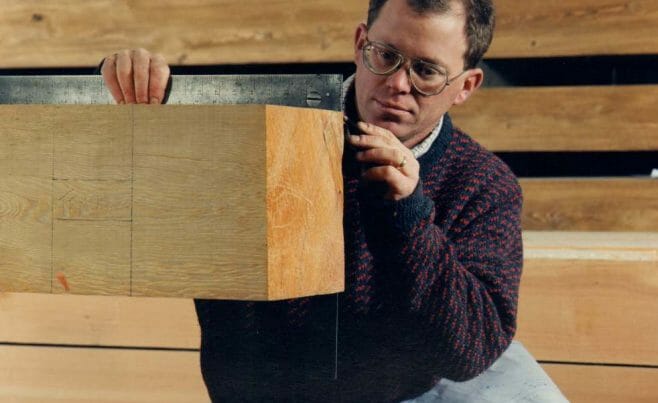

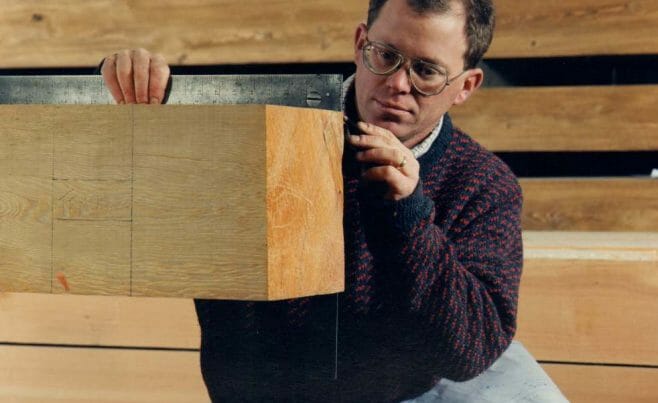

MAKING MEASUREMENTS BEFORE CUTTING

The layout is an important first step in the process of fabrication. Making sure that the measurements are correct and the markings are accurate, ensure that the cuts our craftsmen make will be correct.

16" TIMBER SAW

A TIMBER SAW FOR BIG CUTS

Beam saws are used to cut the timbers to length, and to do angle cuts and compound cuts as shown here.

CUTTING TIMBERS IN OUR WORKSHOP

The timber saw is one of the most used tools in the shop.

8" CIRCULAR SAW

SMALLER TIMBER SAW

Smaller saws are used to do the finer cuts.

12" HAND HELD PLANER

ELECTRIC PLANER

The hand held electric planer is a tool used to plane and chamfer the timbers and create a smooth, planed finish before the wood is stained.

DARIO BAND SAW

BAND SAW

The band saw is a helpful tool when cutting more complicated and decorative timber frame designs.

CUTTING WITH A BAND SAW

The band saw is used for cutting curves and for other cuts that require an exacting level of accuracy.

CUTTING TIMBER WITH THE BAND SAW

The band saw allows are timber framers to cut curved arches and trusses.

SLOTTING MACHINE

CUTTING SLOTS IN TIMBER

The Slotting machine is used to cut slots on the ends of the timbers.

USING THE SLOT CUTTING TOOL

Slots allow the Timbers to fit together securely and tightly once the frame is assembled.

TIMBER FRAME SLOT CUTTER

The Slott Cutter is versatile and can be used to cut a slot anywhere needed.

MORTISING MACHINE

CUTTING MORTISES

Cutting mortise pockets for tenons to fit into is the mainstay of traditional joinery.

MORTISE CUTTER

Mortise pockets are cut so that tenons may be inserted and secured with pegs.

DRILL STAND

STANDING DRILL

A hand held drill press is the tool used to bore the holes for pegs and bolts.

DRILL FOR PEGS

Peg holes need to be drilled anywhere a connection will be made to connect two timbers together.

DRILLING FOR PEGS

The peg holes are essential for the timber connections that use inserted pegs to secure the connection.

STANDING DRILL

The standing drill can be used at multiple angles.

CHISEL & MALLET

USING THE MALLET

The mallet is used to strike the chisel to provide the force needed to make the cuts.

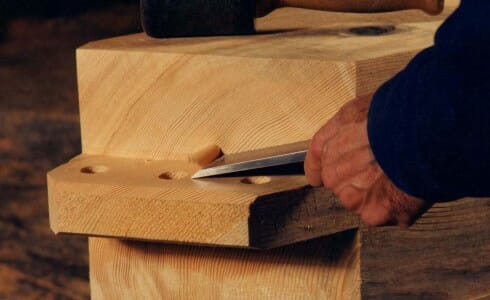

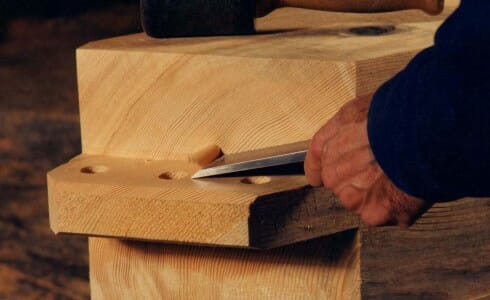

USING THE CHISEL

The chisel is for more delicate and small cuts.

THE CHISEL

The chisel is used primarily for fine details and finishing work.

SLICK

THE SLICK

The slick is used on the surface of the timbers to provide a finishing texture.

SANDING

SANDING

Here a soft sander is used to sand a curved timber.

SANDING

hand held sanding tools are used to sand and finish timbers.

SANDING

Sanding is an important finishing step to ensure that the timbers are smooth to the touch and to prep them to be stained.

PEG SHARPENER -DISK SANDER

PEG SHARPENER

The peg sharpener is used to make the pegs that are used to secure the connections in a timber frame.

ADZE

THE ADZE

The adze is a long, held tool that is swung along the surface of the timber making light cuts and creating a hand hewn finish.

FINISHING

STAIN

Stain is applied as the last step of the fabrication process.

STAINING

Stain can be applied with brushes, wipes, or sponges.

WOOD STAIN

There are a variety of wood stain choices that will change the color and appearance of the timber.

TIMBER FRAMERS WORKBENCH

TIMBER FRAMERS WORKBENCH WITH HAND HELD TOOLS

A typical work bench in our work shop will have saws, drills, and a variety of hand held tools used for cutting, finishing, and sanding timbers.

WORKBENCH WITH TIMBER SAWS

Bigger tools are kept at different stations around the workshop.

WORK BENCH WITH TIMBER FRAME TOOLS

The typical tools on a Timber Framers work bench.