Our crew often travels to the job site to assemble and raise frames. The same craftspeople who cut the frame also put it up. Most of our post and beam frames can be erected in a matter of days.

We pre-assemble parts of the frame in our shop whenever possible. Then, once on site, we use large cranes to raise the frame. In less than a week, a timber frame can be complete and ready for a local contractor to finish.

The Assembly & Raising Process

- Timbers are organized and packaged for shipment

- Timbers are delivered to the job site

- Bents are assembled and stacked

- The crane arrives

- The crane lifts the bents. They are connected and set

- Between each bent that is set, the ridge is dropped into place and either purlins or rafters are installed

Scroll down the page to see the process and techniques we use to assemble and raise custom timber frames and check out this time lapse video of a timber frame barn raising. Check out the tools we use to raise a timber frame.

Assembling & Raising A Timber Frame

Label Timber

The assembly & raising process begins after fabrication. Every cut of timber is labeled for its place in the frame, and then it's organized into bent material, purlins & or rafters, and connectors. The organized timber is packaged for shipment.

Fabrication

Ship Timber

The parts for the timber frame are delivered "knocked down" to the job site on 48' tractor trailers.

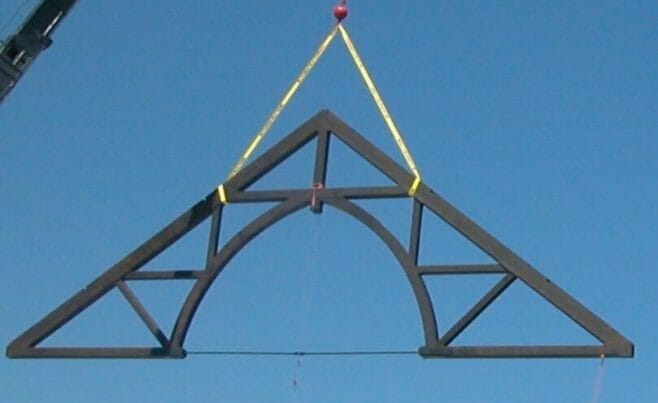

Assemble Bents & Trusses

Bents and trusses are assembled on the ground. In this picture, a girder truss is being assembled. Come-alongs (the things with the handles) help pull the timber together and hold it tight while pegs and bolts are driven into place.

Organize Bents & Bays

Once on site, the bent pieces are put close to the building to be pre-assembled, and the purlins, connectors and ridges are put where the crane can reach them on the day of the raising.

Lift Bents

The crane arrives on site to lift the pre-assembled bents. This photo shows a section of a building that was pre-assembled on the ground being lowered into place by a crane.

Position Bents

Bents are brought down and secured to the deck and temporarily braced with 2x4 cross bracing. This photograph shows timber framers walking the bent to align the bottom of each post with its proper position.

A Rafter Being Installed

A timber rafter is being placed between bents. Notice the notches in the bottom of the rafter and in the top of the bent.

Connect Bents

Once the bents are in position, the 2x4 bracing is released and the bents are spread open a few inches so the connectors can be put into place.

Drive Pegs

When the connectors are in place, the bents are pulled tight with come alongs and the connectors' tenons are pegged tight with hardwood pegs that are driven into place by hand.

Install Purlins

Next, purlins are lowered into their pockets. Then hardwood wedges are driven into the purlin pockets to secure the joint.

Install Sections

Entire prea-ssembled sections are picked up and lowered into place. This assembly will top the ridge a barn frame.

Tighten & Finish The Frame

Finally, the timber frame is tightened and completed except for the tree on the high gable. Nailing a tree to a timber frame is a good luck German tradition that builders carry out even to this day.