Understanding Raised Bottom Chords in Timber Trusses

At Vermont Timber Works (VTW), we design and fabricate a wide range of custom timber trusses for residential, commercial, and public structures. Timber trusses are an excellent way to open up interior spaces — allowing for vaulted ceilings that bring in more light and create a spacious, airy atmosphere.

While VTW often provides timber trusses as part of a complete timber frame package, we also frequently supply just the roof trusses, with the remainder of the structure conventionally framed to help reduce overall project cost.

The Appeal of Raised Bottom Chords

Many owners, architects, and designers approach us looking to maximize interior space and enhance the visual lightness of their truss design. One of the most common requests during the design phase is to raise the bottom chord, sometimes called the tie beam.

At first glance, raising the bottom chord may seem like a simple aesthetic adjustment — it creates a taller, more open ceiling. However, this small geometric change dramatically alters how forces flow through the truss and can substantially increase material and fabrication costs.

Why Raised Bottom Chords Increase Cost

The most economical timber truss is typically the most structurally efficient one. In an efficient truss, member sizes can be kept smaller, loads are balanced, and connections remain simple.

When the bottom chord is raised, the truss geometry becomes less efficient. Member sizes often need to increase to handle higher forces, connections become more complex, and additional steel hardware is often required to maintain structural integrity. These changes not only add to fabrication time but also raise overall cost.

Comparing Three King Post Truss Designs

Below are three king post truss configurations (including modified versions) with the same span and roof pitch. The only variable is the height of the bottom chord. Each truss carries a nominal 1 lb unit load at the peak, with negative values indicating compression and positive values indicating tension.

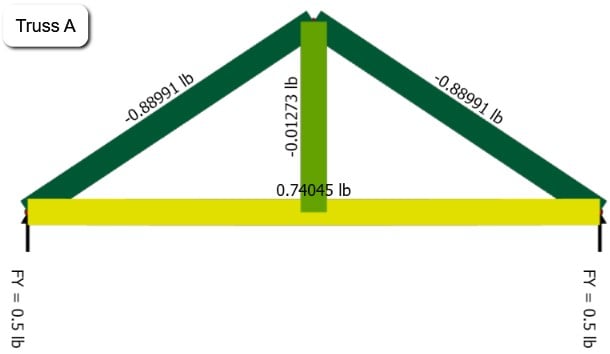

Truss A – Traditional King Post Truss

In this classic design, the bottom chord connects directly to the top chords at the eave. This configuration is well-balanced — all member forces remain below the applied load, and the eave connection is straightforward, occurring directly over the support. For moderate spans, this joint can often be a traditional timber bearing connection, avoiding the need for more expensive steel hardware.

Typical Forces in a king post truss.

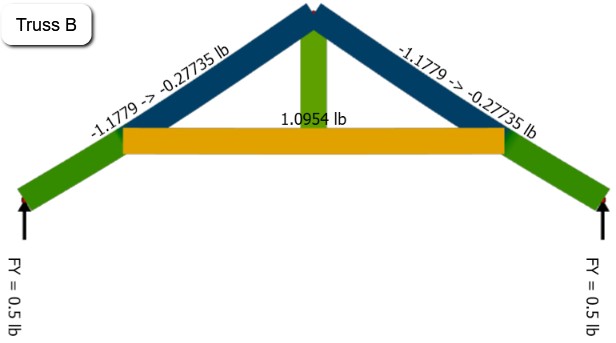

Truss B – Bottom Chord Raised ~1/3 of Total Height

When the bottom chord is raised about one-third of the truss height, geometry changes reduce efficiency. Both tension in the bottom chord and compression in the top chord increase. The connection between the top and bottom chords must now occur within the top chord itself, introducing additional bending forces to the top chord. The top chord may need to be larger to handle these stresses, and a steel connection is often required to safely transfer loads — adding both complexity and cost.

Forces in a king post truss with a raised bottom chord.

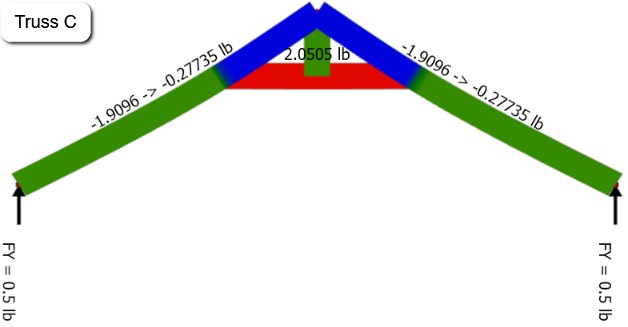

Truss C – Bottom Chord Raised ~2/3 of Total Height

This variation amplifies all the challenges seen in Truss B. As the bottom chord is raised higher above the eave, the tension in the bottom chord and compression in the top chord increase exponentially. This results in significantly larger members, heavier connections, and higher fabrication costs.

Extreme forces in a king post truss when the bottom chord is raised too high.

Balancing Design, Structure, and Aesthetics

At Vermont Timber Works, we understand the desire to create open, dramatic interior spaces. Our team works closely with architects, builders, and owners to strike the right balance between aesthetic goals and structural efficiency. Whether your project calls for a traditional king post truss or a custom raised-chord configuration, we can engineer a timber truss design that fits your vision, budget, and performance needs.

If you’re planning a project and want to explore whether timber trusses are the right fit, our engineers and craftsmen at Vermont Timber Works are here to help.

📧 Email: [email protected]

📞 Call: 802-886-1917

We’ll work with you to design a timber truss system that’s as strong and functional as it is beautiful.

Great explanation for the forces in a king post truss!