The Timber Framing Process

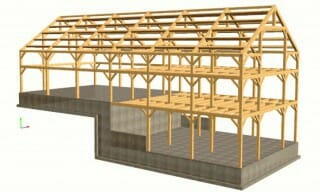

We created this page to help you better understand our framing process from conceptual design to the final installation of our products. The process includes preliminary design, engineering, creating shop drawings, ordering the timbers from the mill, fabrication, assembly and raising. We use the latest in architectural computer design, but still handcraft our timber frames the old-fashioned way because, simply put, it is the best way. As you can see from the photos, our craftspeople carefully select, orient, and cut each piece of timber and produce an elegant, strong, truly impressive finished product. Our timber frame process is based on extreme attention to detail, integrity and dedication to the craft.

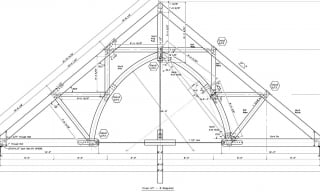

Vermont Timber Works designs and engineers all of the structural heavy timber frames and structural roof trusses that come though the office. As a minimum, they ensure that the state building code is being met. For the design of the trusses, projects range from 16 foot king post trusses to 60 foot double chorded inverted trusses. Timber frame projects range from simple barns and saltboxes to 60 foot octagons.

We handcraft all of our timber frames to suit the needs of each client. We use a variety of woods and finishes. We do not build standard post and beam kits. Instead, we match each clients’ need with a timber frame custom designed for them.

Our crew often travels to the job site to assemble and raise frames. We pre-assemble parts of the frame in our shop whenever possible. Then, once on site, we use large cranes to raise the frame.

Sometimes, Clients chose to assemble the frame themselves or have a contractor or builder assemble it for them. In those cases, VTW will ship and the Timber Frame to you disassembled.

If you’d like to see a timber frame assembly, visit our youtube page for time lapse videos of the process.

Contact

We want to make your post and beam vision a reality! Call us at (802)886-1917 or contact us online today for a competitive price and exceptional customer service.

Our friendly sales people are eager to hear your ideas, make suggestions, answer any questions and help you add beautiful beams to your home, business or community structure.

One more thing, take a look at the YouTube clip of a barn raising in Pennsylvania. It shows that, when you work with Vermont Timber Works, the end result is a structure that is solidly built, handsome, dramatic and entirely one-of-a-kind.