Timber frames are defined not only by the warmth of their exposed wood, but by the way load moves through every truss member, posts, beams, and braces. Modern timber connections blend centuries-old joinery practices with today’s engineering requirements—especially when projects involve long spans, high environmental loads, complex geometries, or hybrid timber–steel systems.

Choosing the right connection style is a balance of aesthetics, structural performance, fabrication complexity, and cost.

If you’re new to timber design, you may also want to read our related posts:

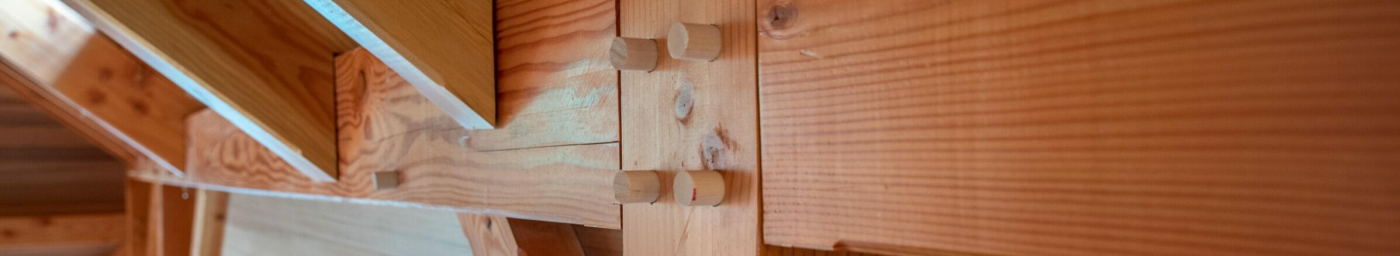

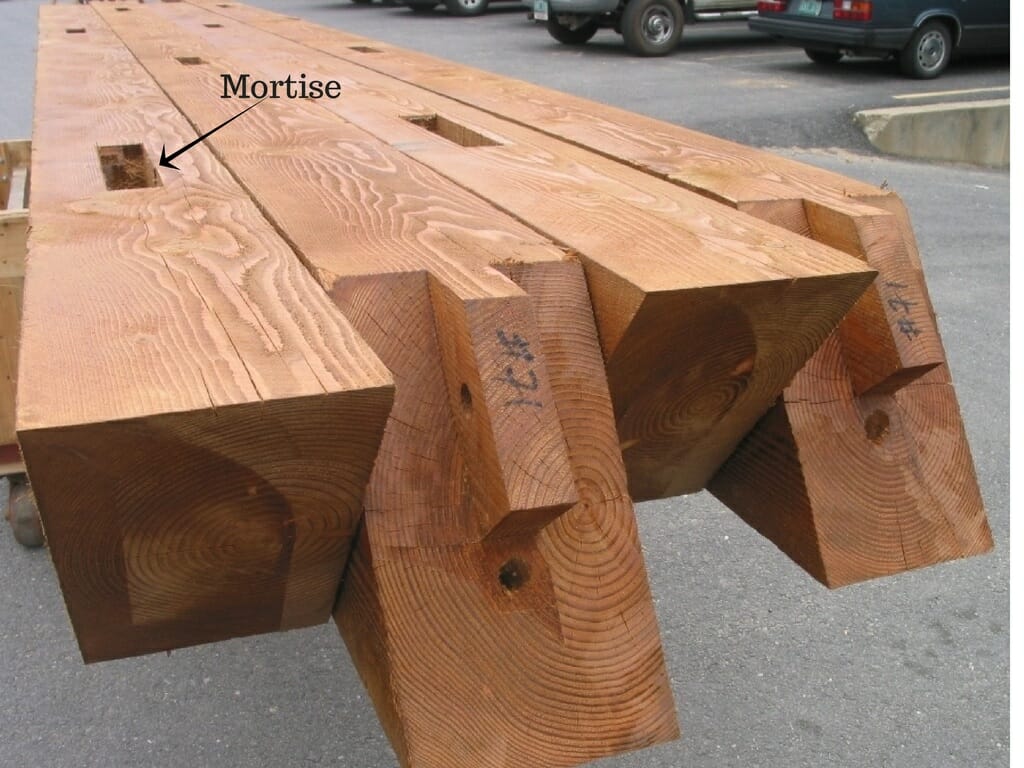

- Mortise & Tenon Connections

The backbone of traditional timber framing

Mortise and tenon joints remain the foundation of the timber framing industry for good reason. When detailed correctly, these joints provide excellent compression load transfer, long-term durability, and unmatched historic aesthetic value.

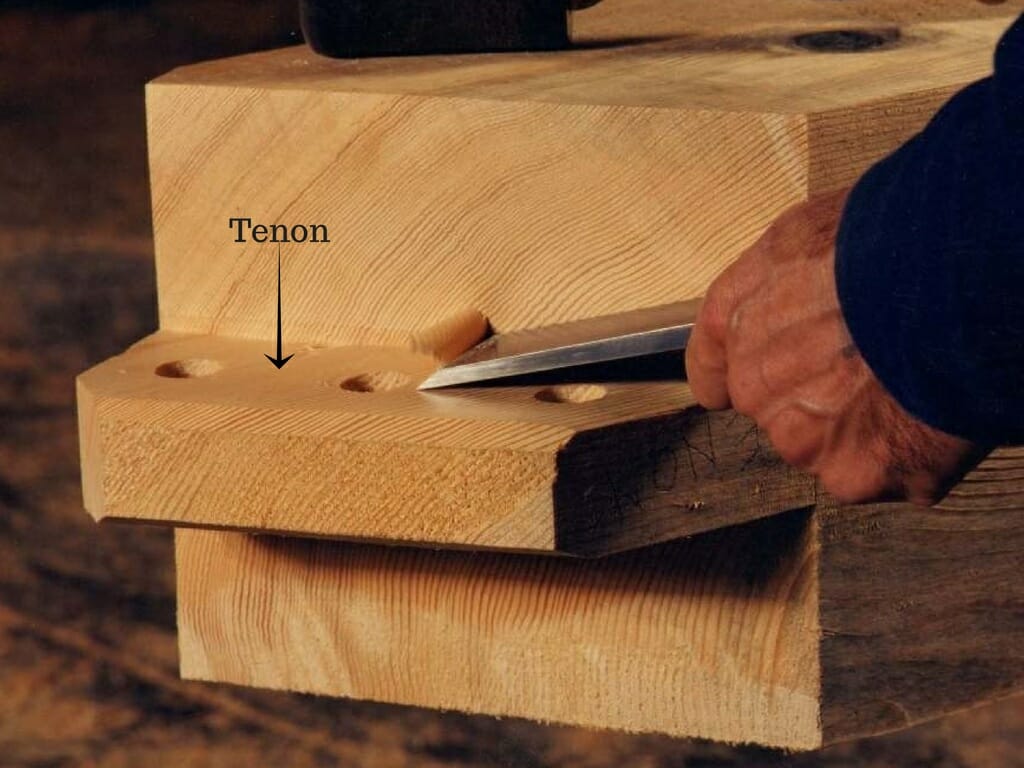

How They Work

A tenon (a projecting “tongue”) is shaped on one timber and fits into a matching mortise (a recessed slot) in the adjoining member. Hardwood pegs are driven through the assembly to lock the members together.

Engineering Considerations

- Excellent for compression and axial load transfer up to certain natural limits.

- Limited tension capacity unless reinforced with steel rods or plates

- Wood movement and shrinkage must be anticipated in the detailing

- Pegs help resist withdrawal but are not a substitute for steel in high-load applications

Traditional joinery remains a great choice for many frames—but engineering dictates when additional reinforcement is needed.

- Steel Gusset Plates

High strength and high capacity for demanding spans

Steel gusset plates are a common solution when visible plate hardware is acceptable—or even desired. They provide significantly higher load-carrying capacity than mortise and tenon joinery alone, making them ideal connections for trusses with long spans, heavy snow regions, and high-tension requirements.

Gusset plates are typically ¼”-½” thick steel plates mounted on both sides of timber members. Through-bolts clamp the assembly together and transfer forces into/out of the timbers and steel plates through bolt bearing.

Engineering Considerations

- Ideal for high axial loads in either compression or tension

- Must account for wood shrinkage; fixed plates without movement accommodation can cause splitting

- Require precise fabrication and tight coordination between timber and steel manufacturers

- Excellent for truss heels, heavy girder connections, and timber-steel connections

Gusset plates blend well with industrial or hybrid timber–steel architectural styles.

- Steel Rods

Slim, strong, and visually striking

Steel rod systems introduce strong tension members without overwhelming the visual weight of the frame. They are especially effective in long-span trusses and contemporary designs where lightness and openness are priorities.

Engineering Advantages

- High tension capacity

- Reduce timber cross-sections needed for long spans

- Control deflection and spread in large trusses

- Simpler and lighter than full gusset plate assemblies

Common Uses

- Modified queen post trusses with a central tension rod

- Diagonal rods for lateral bracing

- Tension chords in long-span girder trusses

- Decorative rod elements that also provide real structural benefit

Rod solutions are a great blend of engineering efficiency and clean visual expression.

- Hidden Steel Connectors

Clean aesthetics with engineered performance

For clients who want the look of an all-wood frame but whose project requires additional structural reinforcement, hidden steel connectors provide the best of both worlds. Over more than 30 years, VTW has developed a wide range of concealed solutions that preserve the timber aesthetic while delivering modern strength.

Hidden Connector Examples

- Housed knife plates recessed inside the timber, bolted and plugged for invisibility

- Internal steel rods fully concealed within drilled-out timber members

- Plate-and-rod assemblies that transfer tension through traditional-looking joints

These systems allow high-performance structures—often with long spans or heavy loads—while keeping the visual focus on the timbers themselves.

How We Select the Right Connection for Your Frame

Every frame we design is custom, and the connection strategy is always driven by a combination of engineering requirements and architectural goals. Key factors include:

- Structural Load Demands

- Snow load (especially in mountain regions)

- Wind exposure

- Span length

- Uplift and lateral loads

- Architectural Style

- Rustic and traditional frames

- Clean, minimal, contemporary designs

- Industrial or hybrid timber–steel aesthetics

- Budget & Fabrication Approach

- Complexity of the joinery

- Steel plate fabrication requirements

- CNC cutting vs. hand-cut joinery

- Field fit and installation considerations

Our engineering and fabrication teams work together to select the right solution for strength, appearance, durability, and efficiency.

Conclusion

Timber frame connections are where engineering and craftsmanship meet. From timeless mortise and tenon joinery to fully concealed steel hardware, each method offers different advantages in terms of strength, cost, and aesthetics.

If you’re exploring options for a custom timber frame—traditional, contemporary, or hybrid—our engineering team at Vermont Timber Works can recommend and design the right connection strategy to match your architectural vision and structural needs.

📧 Email: [email protected]

📞 Call: 802-886-1917