Customers often ask us about using Glulam in their building projects and want to know how this material differs from solid WOOD beams.

And how do you know when to use Glulam in your project and when to use timber?

Glulam made from Douglas Fir.

Glulam

Glued laminated timber, also called Glulam, is a type of structural engineered wood product comprising a number of layers of dimensional lumber bonded together with durable, moisture-resistant structural adhesives.

Glulam provides us with a longer and larger piece of building material that is composed of smaller pieces of lumber. This allows Glulam to be made from younger trees from second and third growth forests, and this makes Glulam relatively sustainable and faster to replenish than larger pieces of whole timber from older, bigger trees.

Glulam is stiff and sturdy and can be bent and shaped. It is able to make longer arches than traditional heavy timber and not require a supporting beam or post.

The strength of Glulam can also be considered more reliable than solid beams because while the individual lams might have a knot or imperfection, the effect of those imperfections will be lessened by the lams nearby that don’t have imperfections and act as stabilizers for one another. A solid log that has an imperfection might not be as strong if the imperfection is large and weakens the whole beam.

Glulam is also less prone to shaking, checking and warping since the smaller pieces of wood have been seasoned and laminated. This generally makes Glulam more stable than traditional timber.

Glulam can also be more expensive than traditional lumber.

When stained, it can look noticeably different than a solid piece of Timber and has a different aesthetic than solid beams.

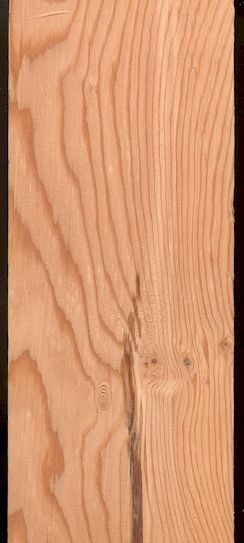

Unfinished planed Douglas Fir

Unfinished planed Douglas Fir

Solid Beams

Solid beams have been used for Timber Framing for hundreds of years. They have a classic look and feel that a lot of people love inside their homes. If you want the classic look of a timber frame home, you’ll choose a solid wood for your Timber Frame.

A Timber Frame constructed out of solid beams of timber will be strong and durable, but there is the possibility that the wood will crack or check. However, engineers account for this and often the cracks or checks don’t affect the structural integrity, they just change the look of the beams. Some people love this look and think it adds to the rustic quality of the timber frame.

Beams constructed from rough sawn Hemlock timber and Birch pegs.

What is most important to you?

When deciding between Glulam or Solid Beams it can come down to a matter of cost, design, and aesthetics. If you want something architecturally interesting and complex, with long arches over a wide open space, and with no beams interrupting the flow of the space, then Glulam would be recommended.

If you can’t justify the cost of Glulam and you’re more concerned with achieving the aesthetic look and feel of a traditional timber frame home, then Glulam would not be the right choice for your project.

It is also quite common to use a combination of Solid Beams and Glulam in a timber frame structure. This allows you to mix and match based on what’s important for you.

For example, you could reinforce load bearing areas with Glulam that won’t be seen and use traditional timber for the rest of the structure. This would give your home the strength you want as well as the visual appeal. Or you could use Glulam for the long arches and do the rest in a heavy timber, mixing both types of appealing wood aesthetics.

Both Solid Beams and Glulams are a strong, durable building material and are excellent choices for your Timber Frame project.

Give us a call if you have any further questions or would like to discuss a project with Glulam or solid timber beams.

Hi

I work for Studio Gang Architects who are designing a building in San Francisco and are thinking of using glulam doug fir beams for an exterior exposed truss structure. The longest span for a beam in this truss is roughly 15ft.

My question is: Should we go with glulam beams or solid timber beams? Issues would be cost, appearance and performance

For a 15 foot span, it is really up to you. The look of the timber is the most important thing as the span is relatively small. Glulams are made up of narrow pieces of wood glued together. They are more stable, and less pron to checking, but the laminations are visible. Solid timber is natural, and looks natural. It can check, which many people feel adds to the character of the wood.

Hello, in my country there is not 8×8 wood size, its a weird wood size and i am thinking about to make beams and posts with glulam for a department. So if you can answer me this 3 cuestion i am going to be really thankfull with you

-Consider you that is a good idea make 8×8 with glulam technic?

-Can i make traditional joints(timbre frame joints no nails or screws) with glulam?

– in my country i can adquire 6×6 and 6×8 in S4S sizes. Do you consider that is better desing a department with 6×6 and 6×8 than a glulam technic?

I am electromechanical engineer but i would like to heard a experience person in the topic like you. Thanks

are glulam beams considered heavy timber for the purposes of determining the construction type in a code analysis?

Hi Sheila,

Yes, Glulam beams would be considered heavy timber in building code and fire code.

Thanks,

Caitlin

I am having a ramada built 15’x13′. Would solid 6″x10″ #1 DF smooth beams not be sturdy enough for this? The pillars are concrete, and I’m being told I need to use gluglam beams.

Hi Alfonso,

It’s hard for us to make that determination without knowing more about the project. Your local experts will be able to advise you on this and make sure you use the right materials for the job.

Thanks,

Caitlin

Three laminated beams (two 9′, one 8′) are long past due for replacement after 45 years of exposure to northern AZ sun and moisture. The beams provide support to a roof overhang, but are not load bearing (they rest on masonry walls and tie the perpendicular supporting beams together, complete the rectangle). Would solid timbers beams be better than glulam beams? The local lumber yard suggested (pricey) Alaskan yellow cedar glulam beams over fir gluclam beams.

Hi Gary,

If the masonry walls are doing the work, any type of beam would be fine. It is just a question of rot resistance. Alaskan Yellow Cedar would be fine – either solid or glulam. If the beams are covered, Douglas Fir would be fine also. We have had good luck with Port Orford Cedar as well.

Good luck with the replacement!

Thanks,

Caitlin

Hi Caitlin

Is the Douglas fir not good enough to just stain and have for covered lanai?

Mahalo

Nija

Hi Nija,

In this instance it’s all in what he wants to do. AYC has much better rot resistance and insect resistance, whereas D. Fir (heartwood only) is okay with rot resistance, and could be susceptible to insect attack. I’d listen to the local mill if that’s what they’re recommending, the upfront cost will probably wash in that if he uses AYC he probably won’t have to replace them again, whereas with Fir he might have to. That being said, with proper maintenance D. Fir should also be fine.

Thanks,

Caitlin

I need two 35′ beams across the top of my walls. Is a 6 x 14 Gluelam better than a sawn beam for support?

Hi Ivan,

You’re right in that the glulam beams would be smaller as they have better strength values. Though either could work, and it would depend on what your structural requirements are. This isn’t really a question we can answer sufficiently without being there. A local engineer would be able to give you a better answer.

Thanks,

Caitlin

i need (5)16 X7 X 40 beams PT to build a floating raft to cary heavy equipment will a laminated beam hold up in salt water ??

Hi Mat,

For more information about ordering beams, you can reach out to us at [email protected] or call us at 802-886-1917.

Thanks,

Caitlin

Hi. I determined that my 18’7″ span requires a 3 1/8×13 1/2 glulam. What is the dimensional lumber equivalent?

Hello Louie,

Ultimately this is unknowable with the given information as there are so many unknowns. You must have used an allowable bending stress (psi) for the glulam that you designed (i.e. 20F = 2000 psi), so you can work through a similar process with your proposed dimensional lumber species and grade. The allowable bending stresses are complied in the AWC – NDS Supplement. That stress then needs to be adjusted with all applicable adjustment factors per chapter four of the NDS.

Or I’d recommend getting a local building inspector or engineer to take a look and check it out.

Thank you,

Caitlin

Good morning! I’ve got 2 commercially constructed arched Glulams built with 2×6 Doug Fir. Each has a beam depth of 21″, finished width of 5″, chord length of 25′, and curvature radius of 150′ (very little arch). I’m wanting to use these in place of trusses for a 2-car carport and am wondering about snowload capacity. If I construct the carport such that each arched glulam spans 22′ (each ends rests on a post), the two glulams are 16′ apart (beam centerline to beam centerline), with perlins between the 2 glulams, can you tell me what lb/sq ft snow load capacity to expect (or how to calculate it)? Thanks!

Hi Mark,

There are so many unknowns that we can’t adequately calculate the snowload for safe building use (i.e. grade of glulam, dead load, roof pitch, unbalanced snow loads, site concerns, ground snow load for his location, etc.) We would suggest looking for a local engineer familiar with the local codes and loads, or the local/town building inspector to help you with this.

Good luck with your project!

Caitlin

In a car their a solid timber beam 5 1/2″ x 13 1/2″ x 22′. Is a glulam in the same size going to be just as strong or stronger than a solid timber beam?

Hi Aaron,

It depends on the grade of the glulam and the grade of the timber. Typically glulam beams have more capacity for their size compared to a comparable timber, but each case is unique.

Thanks,

Caitlin

I’m building a deck in Northern Utah and was told glulams are designed for internal use only. Is there a difference between using 3 2×10’s or 2 2×12’s instead of a glulam?

Hi: I am having a pergola / deck project built abd my GC suggested Glulam. My question is whether the 10 x 20 ft pergola could be built with just 4 posts using glulam or would I need 6 posts? Does glulam come in 20 ft lengths? what would be the cost ?

Hi Elsa,

It is hard to say without doing a proper structural analysis, but six posts would probably be best – you might get away with four if the beams were sized by an engineer depending on the project location and snow and wind loads. Glulams come in very long lengths, 20′ is no problem. If you’d like an estimate on the cost of the Glulams, you could give us a call at 802-886-1917 and talk to our sales staff about a quote.

Thank you,

Caitlin

hi

is Glulam beam stronger than the old fashioned Flitch beam?

Hi Svan,

A flitch beam is made of three parts that are bolted together: wood beams on the outside and a steel plate sandwiched between them. They have some strength advantages, but we rarely use them because of the labor involved and the look of the bolt heads. They do look great in old mill style frames where steel is featured.

Thanks,

Caitlin

Glulam can also be more expensive than traditional lumber. When stained, it can look noticeably different than a solid piece of Timber and has a different aesthetic than solid beams.

Great topic, I also go for a combination of both. Because you can build a timber frame structure that has both solid beams and Glulam beams or cross-laminated timber in the building structure. In areas where the wood isn’t visible, you can go for Glulam. For the rest, you can use timber.

I really liked the article and will apply some of these ideas to my business. Thanks for sharing!

Wowzers! Those solid beams are saweeet! Lol Very nice!

I have just began learning about timber frames. Very interesting form of building, looks quite rugged and rustic yet very luxurious.

As for my garage building project, I think both is needed.

Hi there

I’d be interested to know if glulam can be used with traditional pegged mortise and tenon (non steel ) joints ? If this isn’t often done , then I’d love to know why ?

Thanks

Hello,

I am replacing a porch header 6×6 and posts 6×6. Header is 23′ total span. Maximum span between posts is about 16 feet. Should I use a regular solid beam for 23 foot header? or glulam. My contractor told me regular solid wood would twist/warp over 23′. Any recommendation? Thanks very much!

I need to span 31’ and the glu lam called out is a 6-3/4”x21”

How big of a traditional timber would I need?

Hi Tim,

With traditional timber, you’d probably need to go much bigger. It would probably be best if you hired an engineer who could come up with a different solution.

Thanks,

Caitlin

We just finished a driveway on a new timber built home. Let me tell you, I liked what I saw the whole time. Timber is just so amazing to see in a house and you know it’s going to last!

I’d be interested to know if glulam can be used with traditional pegged mortise and tenon (non steel ) joints ? If this isn’t often done , then I’d love to know why ?

Thanks

Hi Robert,

Pegs can be used in glulams, but you are correct, they generally are not. Most glulams are bolted together due to higher stresses and higher loads.

Thanks,

Caitlin

Hello Caitlin! Looking forward to be working with a home renovation project with you soon. 🙂

Great!

Looking to build out a deck on one of my properties. I do some power washing work. Do you think Glulam would be better since the beams have a tendacy to get cracked and chip? I

Hello,

Glulam or solid beams would both hold up fine. So it would be up to preference.

Thanks,

Caitlin

I think, the only issue when choosing which wood will work well on your project is financial. |

hi do glulam beams shrink in the depth of the beam and if so the likely how would i calculate the shrinkage.

Hi Kevin,

The material used in Glulams is generally construction grade 2x stock and is typically dried to 12-19% moisture content. Therefore, shrinkage is to be expected as the glulam dries to 5-8% moisture, which would be typical for the interior of a building. A 12″ deep glulam may shrink around 1/4″, but all wood is unique and will shrink at different rates. The shrinkage usually is not a problem. Sometimes, when we are using steel connection plates, we will slot one row of holes to allow for some shrinkage.

Good Luck!

Caitlin

I have been searching for a good comparison between Glulam and Solid Beams. Thanks for sharing this helpful guide. It was easy to understand the topic, which is not always the case with some guides out there. I am very satisfied with the quality of this article, so it is really helpful to me!

I regularly build livestock portal frame buildings, using timber. I am interested in replacing the purlins in our current design with glulam, if it will allow for bigger bay/ portal frame centres. For instance I currently use a 9×3 timber beam to span a maximum of 13 feet bay centres. Would a glulam beam of the same dimensions or less, be capable of spanning a longer bay centre with the assumed maximum loadings being the same in terms of deflection?

Hi Simon,

In general, glulams can span further than natural timber, but a professional engineer should have a look at the specific building you are considering and size the beams accordingly.

Thanks,

Caitlin

They both look awesome its a shame that the glulam is a bit more expensive as it would be awesome to see more around. Thanks for the comparison!

In this day and age, It would take me a few years to purchase me a stick of 2x 4 hahaha. The comparison really is helpful though

Is glulam more expensive than solid timber?

both looks exactly the same though. But I believe glulam is for tight spaces, correct?

Would solid 6″x10″ #1 DF smooth beams not be sturdy enough for this?

Just wanted to say that I really enjoyed reading this article. The price of lumber has really increased in the last couple years, but I’ll save this article when I’m reading to start renovating my home.

Awesome article thank you! It’s crazy to see the price difference as well as the other comparisons. thanks

Hello, I am looking to replace a 100 year old structure burned in a forest fire. The new structure has to have a treatment for fire. and all wood has to be #1 or better grade DF. We currently have about 50 feet of snow this season, more is coming. The building is 24 feet by 60 feet. any ideas?

Well I think whatever you choose for your building project, they both look fantastic. I love the look of timber all around!

Fantastic! Should we go with glulam beams or solid timber beams?

We have used both these types of beams in our building project, thay are great.

My personal opinion is always timber. Could be wrong though given the situation.

I think both are suitable options but it depends on where you want to use them. Thanks for going in-depth on the article.

Both great options. Your project will look amazing if you know how to finish it properly and you have good matching tones. Thanks for the explanation!