Students From St. Michael’s School Tour Our Timber Shop

We recently teamed up with St. Michael’s school in CT to build a church timber frame. The frame is going to replace one that was originally built in 1861 that had an addition added to it in 1867. Unfortunately, the original frame failed in 2012 and the building was closed. Recently, the decision was made to re-build the church from the ground up. Vermont Timber Works collaborated with St. Michael’s and Geddis Architects to construct a timber frame for the new church. St. Michael’s school will be located inside the church. The plan is for the new frame to stand for hundreds of years just like the original one did!

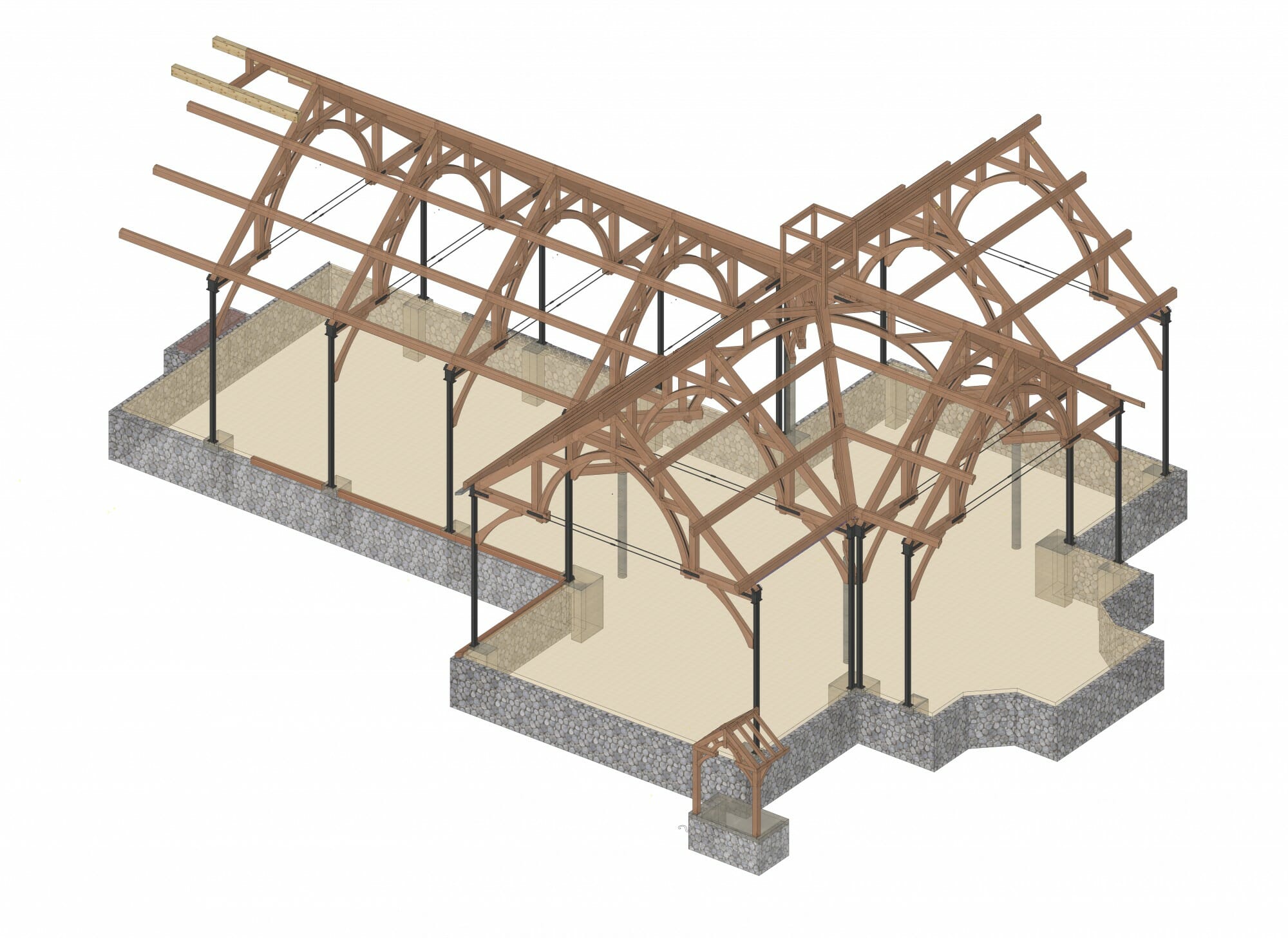

Church Frame Design

This is an image from a 3D model that Doug, our in-house designer, put together for the new church. The frame has beautiful, custom hammer beam trusses that are reinforced with steel tie rods. There are almost 40,000 board feet all together, so it’s a pretty big project. The new design is quite similar to the original.

Students From Saint Michael’s School

The 8th grade students from St. Michael’s, and Father Perkins, came to visit our shop to see the construction of their new frame! They toured the business and walked through the manufacturing process.

Checking Out The Solar Field

The first thing they wanted to see was the solar field. All the power in the Vermont Timber Works’ shop comes from the sun. There’s a solar field in our backyard that is net metered. Sun shines onto panels and the power from that sunshine goes into a grid that stores the energy until it’s needed.

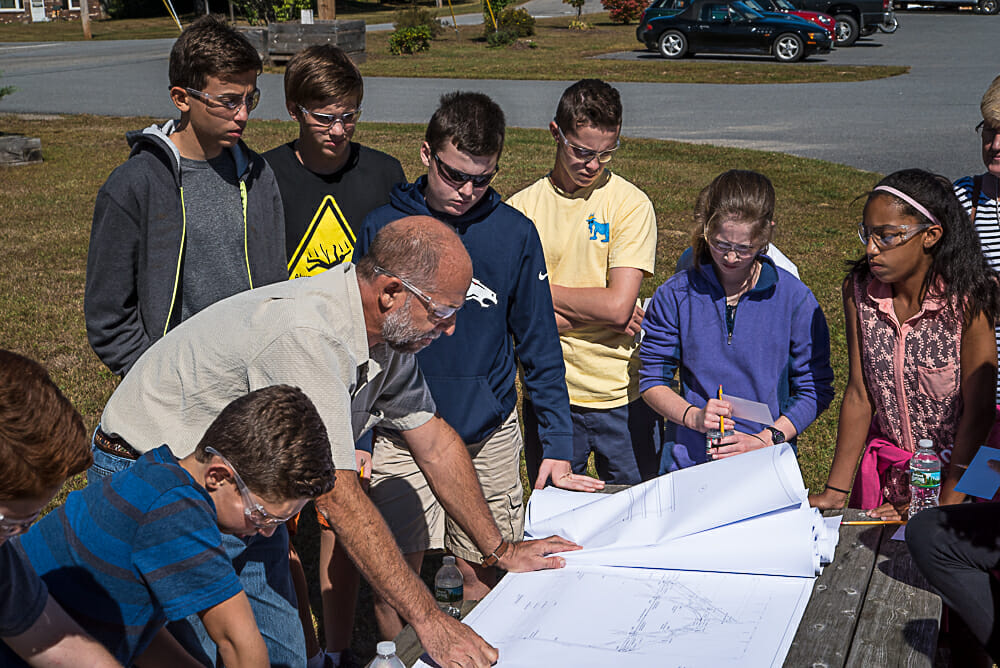

Looking At The Frame Plans

The next stop was to look at the frame plans. For every timber frame, there are shop drawings that show the frame elevations, bent sections, and joint details. Our crew uses the drawings as a reference to cut and assemble the timber.

Laying Out The Timber Cuts

After the students checked out the plans, they headed to the layout section where Dan carefully draws marks on the timber to show where every cut should go. Every piece of timber is labeled with a production number. The students were invited to pick out a piece of timber in the shop, and then find it in the plans to see where their piece belongs in the frame.

Chatting With The Architect

Then they went to chat, beam side, with Barbara Geddis, of Geddis Architects. Barbara was the architect for this frame. Vermont Timber Works and Geddis Architects are a great team. We’ve partnered together for a few timber projects and it’s always a pleasure.

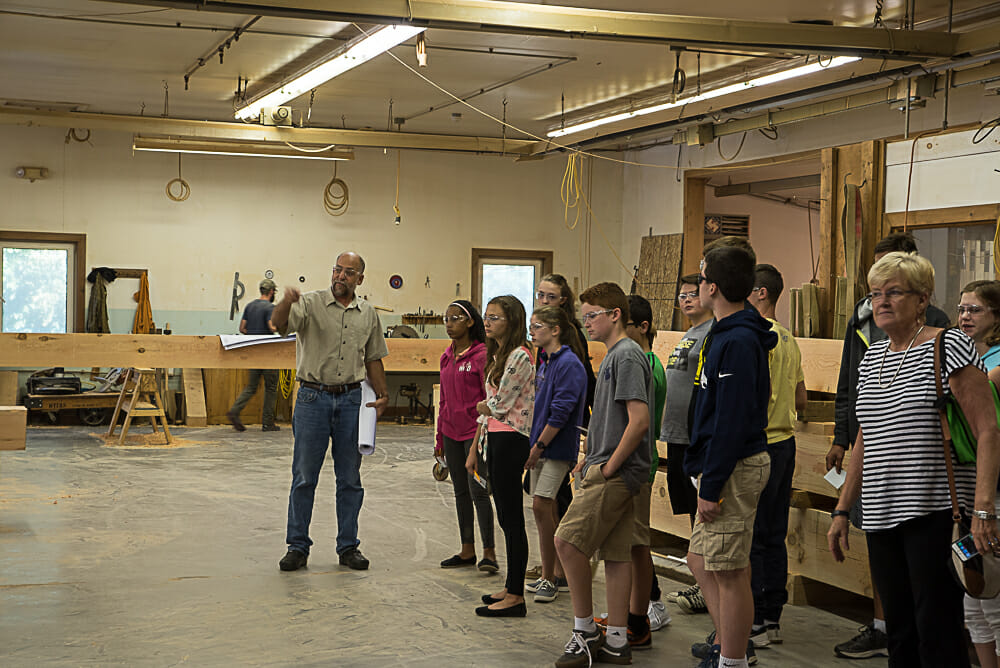

In The Cutting Section Of The Shop

After visiting the layout section of the shop and chatting with the architect, the students moved on to the timber-cutting section of the shop. Doug explained what the crew was doing while the students watched.

Alex Using A Circular Saw To Cut A Beam End

Circular-saws are used to cut beams to length, to do angle cuts, and to do compound cuts. Here, Alex is using a circular-saw to cut a beam to the correct length. We use both large and small circular-saws. The smaller saws are used to make finer cuts.

Amos Using A Chisel & Mallet To Cut A Mortise

The chisel & mallet are classic timber framing tools. Timber frames are connected, & structurally supported, through their joints. We use chisels & mallets to shape precise joints.

Doug With A Bolt & Shear Plate

The frame for this church has beams that will be bolted together. Here, Doug is demonstrating where the bolts & shear plates will go in the timber.

The Stain Section Of The Shop

The final section of the shop, before the timbers are packaged for shipment, is the stain section. The stain used for this frame is Early American. You can also see, in this picture, that earlier in the process these timbers were planed so that they are smooth to touch, and the edges were chamfered (cut so that they are sloped & symmetrical).

The next step in the process will be to ship the timber to the site location! Then our crew will assemble & the raise of the frame. Hopefully it will be exciting for the students to see the evolution of their school’s new building, and special to see their pieces of timber in the final product. It was such a joy to have them in the shop! Here are a few miscellaneous extra pictures from the day:

As always, thanks for stopping by our timber framers’ blog. If you like this post, or have timber work questions, we invite you to get in contact or visit our ask an expert page!

Two More Articles About St. Michael’s New Church: