In this blog post, we’re going to look at some of the Traditional Joinery Methods we use for our Timber Frames. These are traditional joints that have been used in woodworking for centuries and they are strong and durable. While we use Traditional Joinery Methods at Vermont Timber Works, we will sometimes reinforce traditional connections with steel plates and ties that can either be hidden from view or used as decorative accents.

Mortise and Tenon

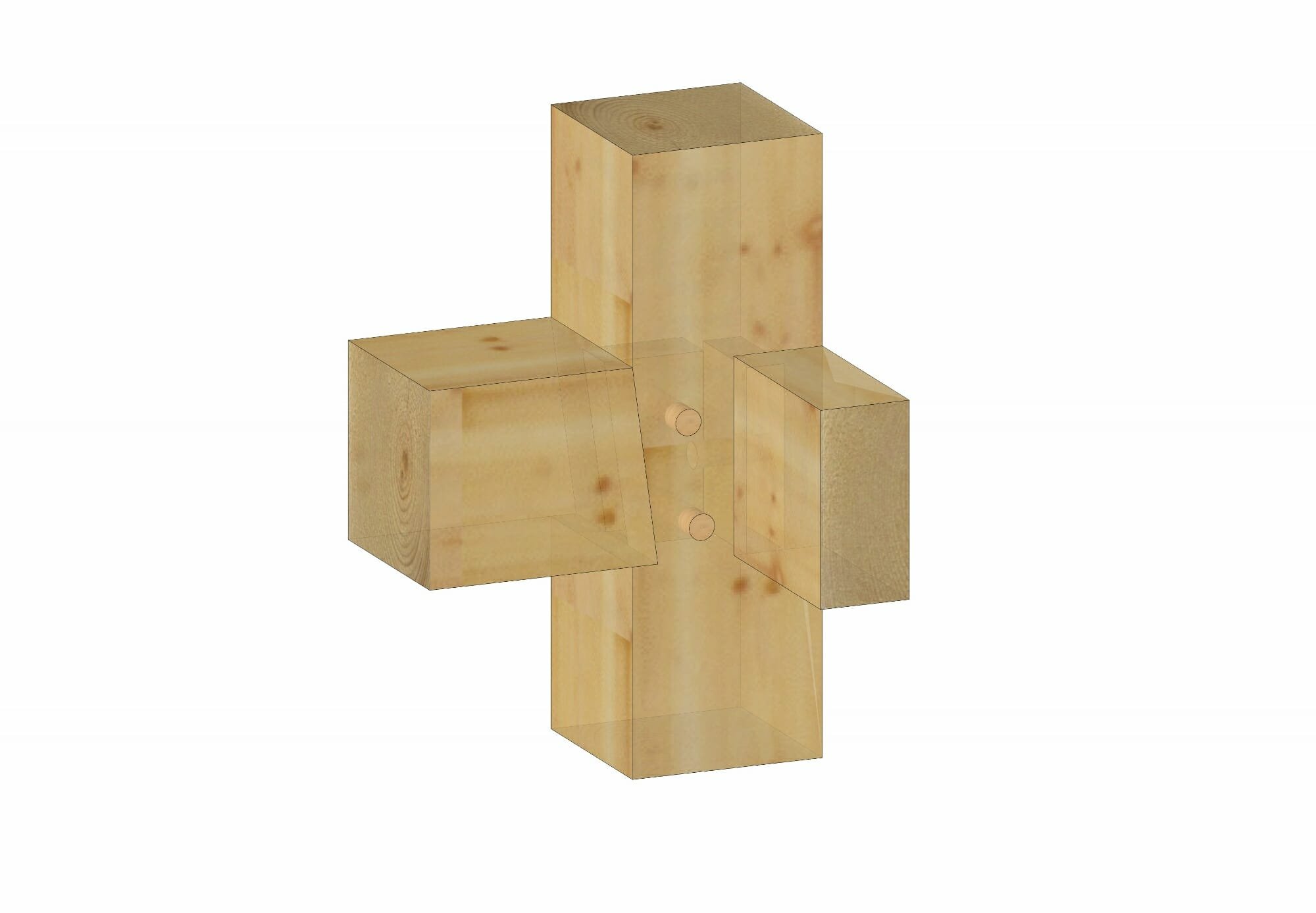

The primary joinery method of the Timber Frame is the basic Mortise and Tenon joint. This joint involves a stub (Tenon), fitting into a hole (Mortise). Then a peg is inserted into the connection site to further strengthen and stabilize it. The Mortise and Tenon joint is the primary type of connection used in Timber Framing with varying degrees of complexity. Below are some of the ways Mortise and Tenon Joints are used:

Dovetail Joint

The Dovetail Joint is a truly ancient joinery technique that has been found on furniture in the tombs of Egyptian Pharaohs and Chinese Emperors. The Dovetail joint gets its name from the diagonally cut fingers that resemble the tail feathers of doves. This shape holds the connection after it has been assembled and makes it very difficult to pull apart. In Timber Framing, the Dovetail Joint is used to connect roof purlins and floor joists to rafters and girts.

Tongue and Fork Joint

Also known as the “Bridle Joint,” this technique features a Mortise that is open on one side and forms a fork shape, allowing the Tenon to slide in. The connection is then secured with a peg. In Timber Framing, this joint is used to connect common rafters together.

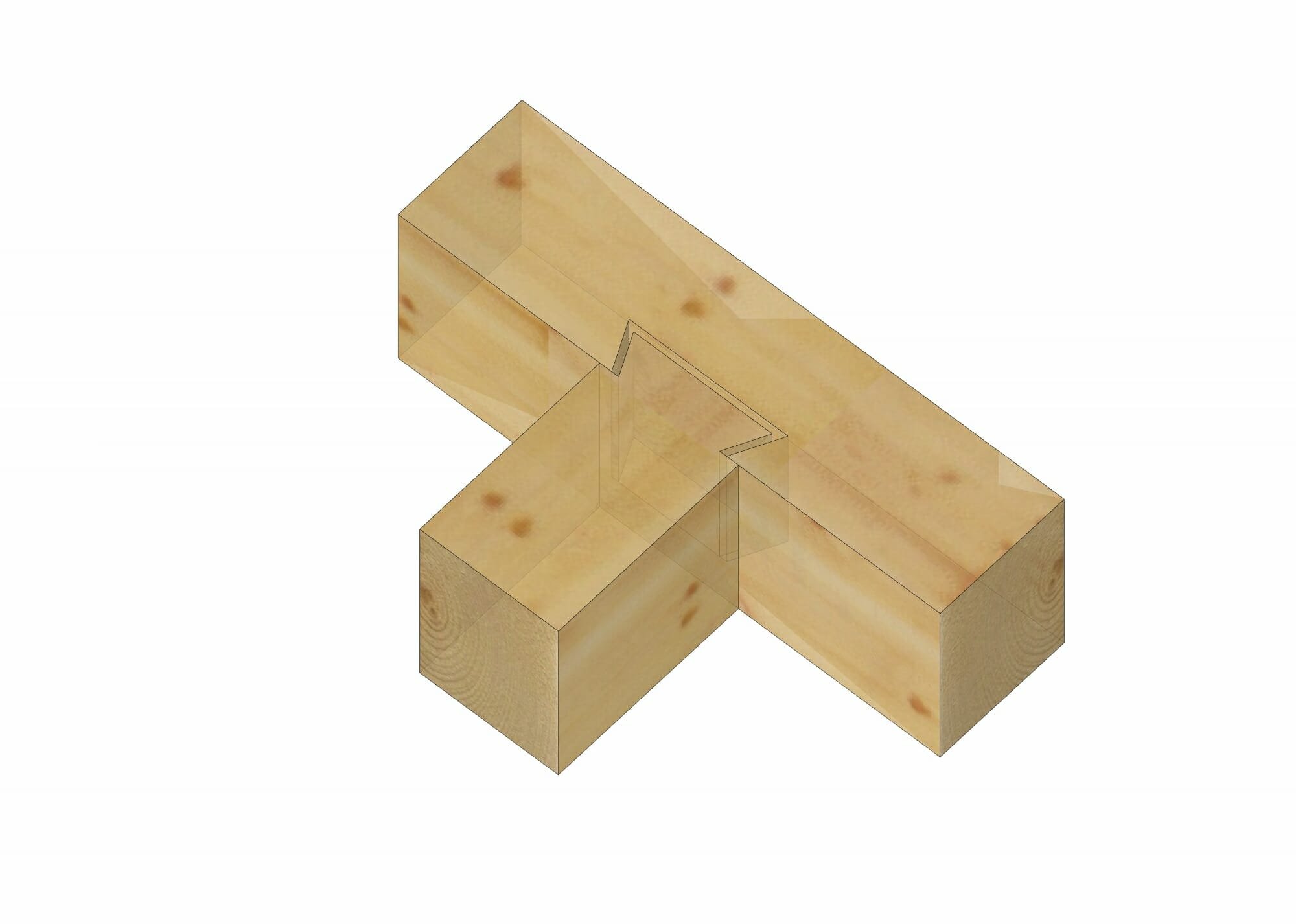

Scarf Joint

Also called the “Splice Joint,” this is a lesser-used joinery technique in Timber Framing. This method involves notches being cut into two pieces of Timber which are then fitted together end to end and secured with a peg in the center of the connection. It isn’t one of the strongest connections and is generally only used when a piece of timber needs to be longer and instead of sourcing a larger piece of lumber, two smaller pieces are joined together.

A scarf joint connects two timbers together to make one.

These are the Traditional Joinery Techniques that we’ve been using at Vermont Timber Works since we began Timber Framing in 1987. Questions about Traditional Joinery techniques? Submit a question on our Ask the Experts page, or leave us a comment below.

very helpful.

Is there a general rule to determine the length of the overlap when utilizing a scarf joint?

The scarf is typically 3 times the width of your timber so for example if you’re using a 6×6 your scarf would be 18” long.

HAVE WHAT I WAS TOLD IS A GUNSTOCK JOINT IN ONE OF MY OUTBILDINGS ON MY FARMSTEAD AND WAS TRYING TO FIND OUT …. WHEN ,HOW ANY WHY WAS IT A CHOSE TO USE. IT IS USED TO SUPPORT WHAT I BELIEVE WOULD BE CALLED THE ROOF PLATE. IT IS AN INTERESTING JOINT. THANKS

indeed

My soninlaw makes timber framed buildings, he knows all the joints and pegging etc, I would like to buy him a poster for his workshop showing all the joints used in traditional oak framed buildings.

Do you supply one, or do you know where I could obtain one.

Hello,

That is not something we could supply and I can’t think of where you’d be able to get something like that. Sounds like a nice gift though!

Good Luck,

Caitlin

This shape holds the connection after it has been assembled and makes it very difficult to pull apart.

Wow! I’m truly astonished by your post and the incredible insights you’ve provided about Dovetail Joint . Your thoughts have completely captivated me, and I’m eager to explore the subject further. The dedication and exhaustive research you’ve poured into this article are undeniably remarkable. Thank you for generously sharing your knowledge and expertise!”