Why Should We Build a Timber Frame Home?

Timber frame homes are beautiful spaces to live in and to entertain in. You will enjoy being in your new home, being surrounded by natural wood, open space, high ceilings and large windows. Your house guests will also love coming over to enjoy the home with you.

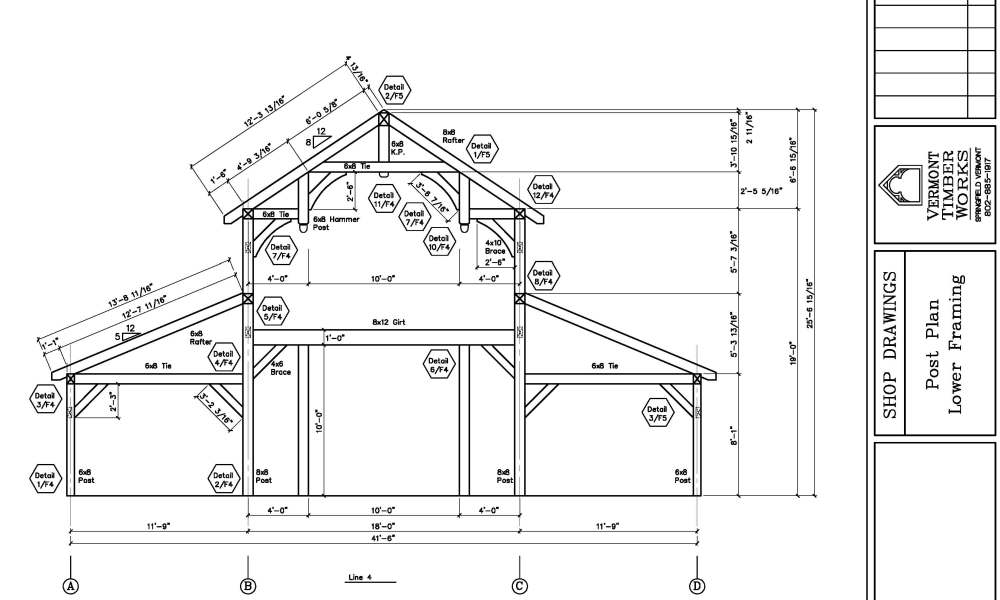

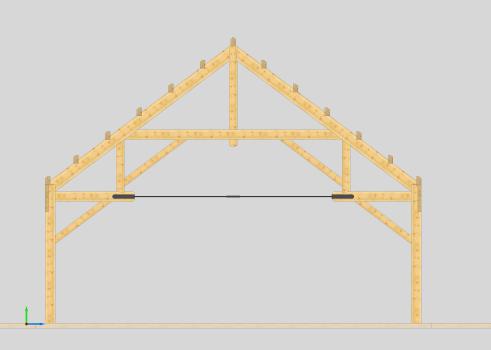

Timber frame homes are different than conventionally framed homes because the structure is in the beams, which allows for wide open spaces between the posts and beams as well as room for big, bright windows. Timber trusses add to that flexibility with spans up to forty feet or more. Cathedral ceilings just come with the timber frames. Attic spaces found under the roof in conventionally framed buildings are not needed in a timber frame, giving timber framed rooms loft and height.

Timber frame homes are super energy efficient when enclosed with SIPs (structural insulated panels), and they allow for great expanses of glass.

Timber frame homes last for hundreds of years. In fact, all of the colonial homes in America were timber framed and many are still standing. Timber frames homes in Europe are hundreds of years old. With proper care, timber frames are resistant to rot and are naturally fire resistant as Type IV construction.

Where Can I Buy Wood Beams for My Home?

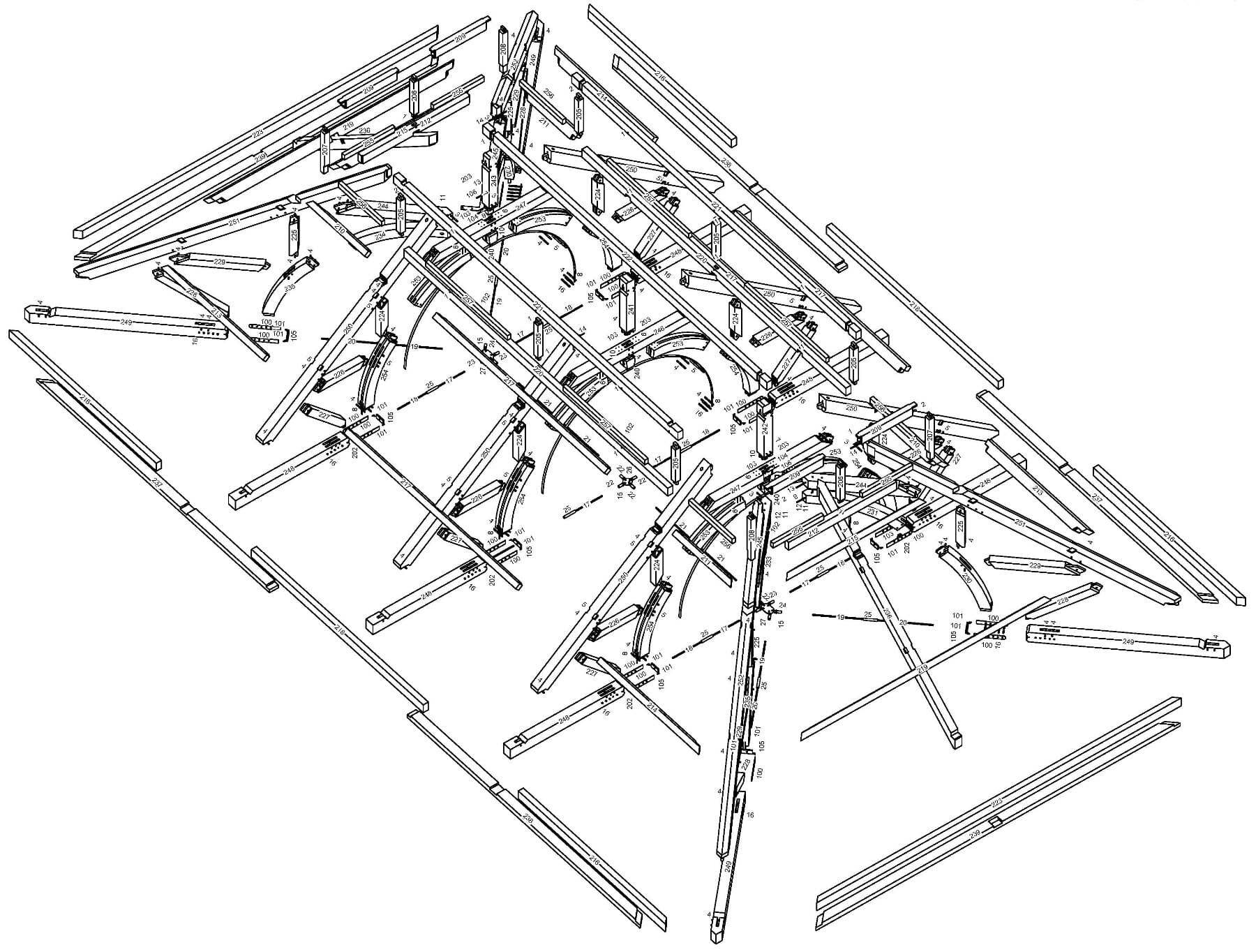

Vermont Timber Works sells prefabricated wood beams, post and beam frames and timber frames for for homes, barns, pergolas and pavilions for delivery nationwide and internationally. VTW has shipped timber beams throughout the United States, Alaska, Canada and the Caribbean. If you need a timber frame, timber trusses or prefabricated wood beams, Vermont Timber works is your source!

Does Vermont Timber Works have standard designs or is all of your work custom designed?

We do have standard styles that we use and customize for each client’s individual needs. For instance, everyone loves the Fancy Texas Barn , which can be used as a house or a barn. We have used the style of that timber frame in many of our projects, modifying the length, width and height for each of our clients. To get an idea of different timber framing styles, visit these pages: Timber Framing Bent Styles | Timber Trusses | Basic Barn Styles . A timber frame, or timber frame elements can be adapted to almost any home design. Give us a call with your ideas and sketches, and we will work with you and your architect to design the perfect timber frame for you.

How Much Does a Timber Frame Cost? Can you give a price per square foot?

Because every timber frame we build is custom and unique, this is a difficult question to answer without knowing exactly what design you have in mind. Things like size, wood species, location, etc will all determine the price of your frame. Frames are engineered to meet site-specific snow and wind loads. Frames on the sea coast or in the mountains are engineered for higher loads and therefore they are more expensive. Wood species is also a factor, as native hemlock is less expensive than free of heart Douglas fir or oak. Complexity contributes to the cost as well, as a fancy hammer beam frame is much more expensive than a simple truss design. The best way to determine the cost of your project is to give us a call and talk through the options and come up with a preliminary design. Once that is done, we will provide you with a firm quote.

How Do You Insulate a Timber Frame or Post and Beam Home?

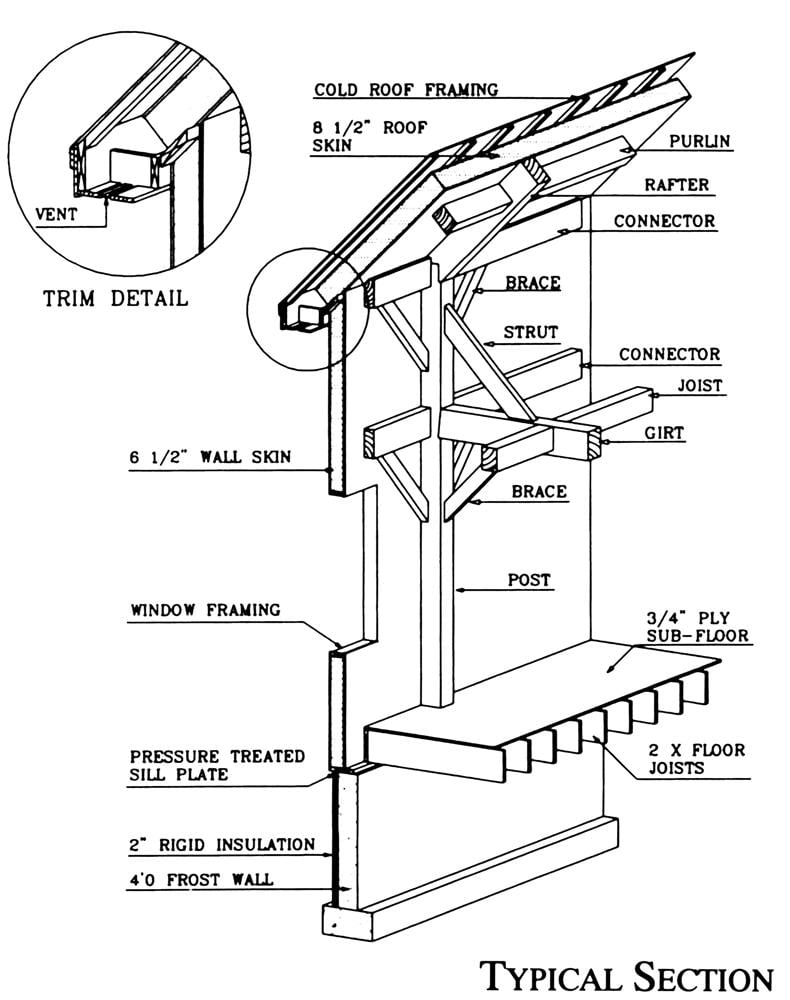

There a several ways to insulate timber frame and post & beam homes. A popular way is with SIPs (Structural Insulated Panels). SIPs are super insulating and super efficient. The outside layers of a SIP are made from OSB (Oriented Strand Board) and the inside is super insulating foam. SIPs come in panels that are four feet wide by up to twenty feet long. They are screwed directly to the timbers and very quickly form the walls and roof of the home. Windows and doors can be cut into SIPs anywhere. The foam is cored out at the edge of the window or door opening and filled with conventional wood framing. The windows and doors are then screwed to SIPs. The disadvantage of SIPs is the cost. They are very expensive. Eventually the savings in labor energy costs will help to offset the expense.

Another option is to conventionally frame 2x walls and roof and attach them to the timber frame by either infilling the 2x framing between the posts and beams or by building the wall outside of the frame making a shell around the building. The 2x framing is then insulated with rock wool or fiberglass insulation. (Spray foam could also be used, but Vermont Timber Works does not recommend spray foam due to moisture infiltration and potential rotting problems down the road). The advantage of using conventional 2x framing to form the walls and roof and insulate a timber frame is the lower cost compared to SIPs, particularly when there are a lot of window and door openings. Another advantage is the ease of running electrical wiring and mechanical chases in 2x framing. Wiring in a post and beam home that is enclosed with SIPs requires chases pre-formed in the SIPs, or using boxed baseboards and cornices.

A third option to insulate a timber frame or post and beam home is to use SIPs on the roof where continuous foam insulation is the most effective, and conventionally frame the walls where many doors, windows and mechanical elements make SIPs too expensive.

What are SIPs (Structural Insulated Panels)?

SIP stands for structurally insulated panel. It is a super insulated panel that has OSB (oriented strand board) sheathing on both sides. SIPs provide the structural skin of a building and often can be used to resolve lateral loads. SIPs are great for roofs as they provide uninterrupted super insulation. They come in different thicknesses depending on the required “R” Value. the higher the “R” Value, the better insulating properties the SIP will have. The foam cores are made of various materials – the more expensive foam cores are thinner and have a higher “R” value. SIPs do require a “cold roof” above them to dissipate the natural moisture that migrates through all buildings and will cause the OSB laminated to the SIP to rot over time if it isn’t given a cold roof to escape through. SIPs are sometimes great on the walls too because of their super insulating properties and the speed of installation. Other times conventional 2x framing is better for walls, like when there are a lot of windows and doors. It is also easier to run electrical wiring and plumbing through conventional 2x walls. You can read more about SIPs on our Wall and Roof Systems page.

What Maintenance is required for a Timber Frame?

Timbers require very little maintenance. The beams are shipped from our shop with one or two coats of finish. Once a final coat of finish is applied in the field by the painter, there is little more to do on the inside of the building. For beams that are outside, they need to be maintained like any other exterior wood with a coat of sealer, paint or stain every few years to keep them looking fresh and to guard against rot.

How Long Will it Take to get my Timber Frame Delivered?

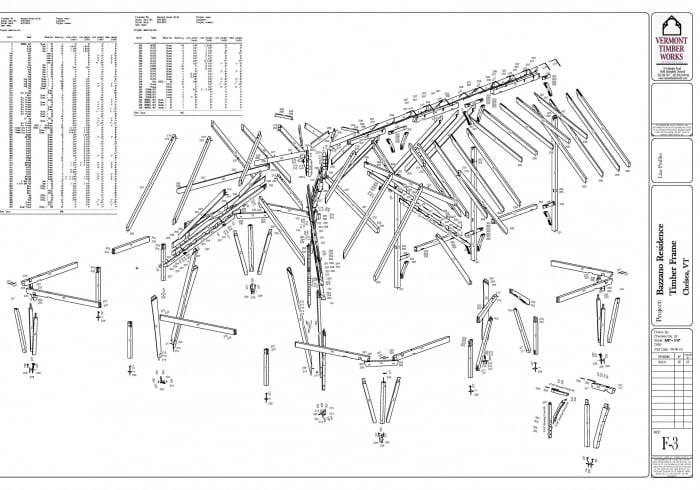

It will take a few weeks to customize and approve the design, assemble the quote, and order the materials. After that, you can expect your Timber Frame to be delivered in 10-14 weeks from the time we receive approved shop drawings back from you. The Timber Framing Process page explains the steps, including design, engineering, shop drawings, approvals of the design and drawings, fabrication, packaging and delivery.

I'd like to Use Wood I Already Have for my Home. Is that possible?

It is possible, and it is fun to use the timber from your land in your home. Some things to consider would be the current condition of the wood. If it’s still in tree form you’ll need to have someone cut down those trees, and then send the wood to a lumber mill. If it’s already milled, you’ll have to consider its condition and the size of the timbers you have. Once it’s been milled, you would ship it to us and we would fabricate the timbers into your house frame. Often there is extra labor and shipping on your end, so it is not always less expensive to use your own wood, but it does make a great story at the parties you will soon be hosting in your new timber framed home!

Do I need to Find an Architect to Design My Home?

It’s not a requirement but it will be helpful to work with an architect or design professional who can design you a complete home that is exactly what you want. That will ensure that the home you’re building and the timber frame VTW designs for that home is exactly what you have been envisioning and that everyone involved in the project shares the same vision. We have designed many timber frames for clients who have not hired an architect. Either way, our timber frame shop drawings will be signed and stamped by a structural engineer so you can rest assured that your timber frame will meet all of today’s structural building requirements. We have worked with many architects over the years, and some are listed on our “Great People We Have Worked With” page. If you need to find an architect for your project, give our sales staff a call and they will try to help you out with several possibilities. The important thing when choosing an architect is being comfortable with them and having a good design rapport with them. They don’t necessarily need to have timber frame experience, we can help with that.

Can You Use Reclaimed Wood in a Timber Frame?

Yes. If you’d like us to use reclaimed wood for your frame or for part of the frame, let us know and we can source reclaimed timber for you. A word of warning though; often reclaimed wood is not as structurally sound as new material. While it is beautiful, repurposed timber may have embedded rot or may not meet today’s grade specifications. Click here to learn more about reclaimed wood.

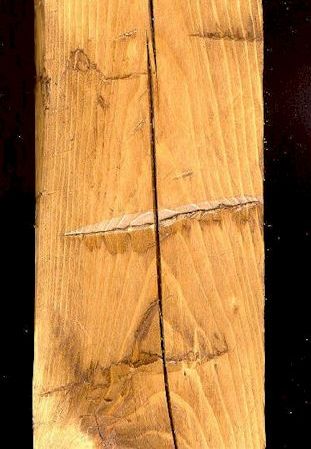

Will the Timbers Crack and Twist Over Time?

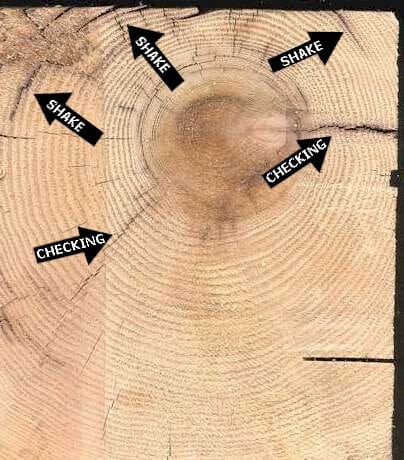

The timbers and beams will probably crack (check) and twist over time. It is the drying of the wood that causes a timber to check and twist. It adds to the unique nature and beauty of timber framed buildings. All timber used in timber frames and post and beam homes is “green” meaning that it was cut and milled from a tree that was recently harvested. Even kiln dried timber is basically green as the kilns only guarantee a specific moisture content to a depth of one inch. On an 8×8 timber, that means that 6″x6″ of that timber will still be green after kiln drying.

When a timber dries, it dries around the growth rings. Since the growth rings in the center of a tree are much more dense than the outer rings, the outer rings will have more moisture content and will shrink more that the inner rings. That extra shrinkage on the outside causes the timber to “Check” (or crack). The check will terminate at the center, or bulls eye of the timber. Checks do not travel all the way through a timber and therefore do not structurally compromise the timber. Learn More about Shake and Checking in Heavy Timber. Timber Checking Blog.

If I Buy the Timber Frame From You can I Put it Up Myself?

Yes! We can make sure the Timber Frame Home design is exactly what you imagined, we can fabricate the timber frame, ship it to you, and then you can erect yourself with technical assistance from our team. We are just a phone call away for free technical support and will also give you a line item on your quote for an on-site consultant to travel to your job site and help your local crew raise the frame. Read about putting post and beam frames up on our Assembly and Raising page. Below are a few photos of timber frames that local construction crews raised.

Do I need Plans or Drawings Before I Can Get a Quote for My Timber Frame?

Having drawings or plans already prepared when you contact us helps us provide you with a more accurate estimate for the cost of your timber frame, and gives us a clearer idea of what you’re looking for. That being said, it is not required. Some clients send images of projects that they like to give us a sense of what they are looking for. In all cases, we always strive to design a frame that meets each client’s vision.

Will You Work with an Architect or Contractor of My Choosing?

Absolutely. We have a good working relationship with many architects and building partners and will be happy to work closely with any other company or building professional you chose to be apart of your project.

Where Can I find Someone Who Will Design a Home That Will Incorporate a Timber Frame?

Often times we recommend people start with sketches and your own research and find an architect or designer whose work you like. You can also visit our Great People We Have Worked With page to find companies who we have collaborated with in the past. After a set of plans or drawings have been made, we can design a timber frame that will work with your plans and continue to work with your designer throughout the process.

Do I Need to Have Knee Braces in My Timber Frame?

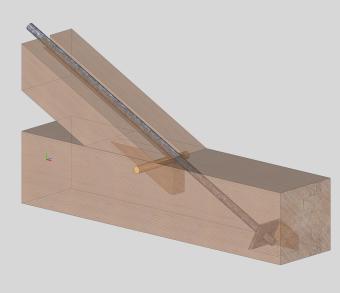

Knee braces are the angled members that are often seen connected to a vertical post and a horizontal beam above. They can serve several purposes including providing lateral stability for the timber frame, supporting the beam above or just looking nice. Curved knee braces are pretty, decorative elements. Timber knee braces may not be required if the lateral loads are resolved in the wall system. Sometimes knee braces get in the way of window and door openings. In that case, they can be removed if we can find another path for the lateral loads. Read more about Timber Frame Engineering.

What are Lateral Loads in a Post and Beam Frame, and Why do I Care About Them?

Lateral loads come from wind and seismic forces that act on the frame. Wind is everywhere and blows at different velocities. Earthquakes are found in many places, some that you wouldn’t expect. As we all have seen in the news, wind can tear a roof off of a house or blow it over completely and an earthquake can bring a building to the ground in seconds. We take all of those factors into consideration when designing our timber frames and post and beam frames. Designs on the coast take hurricane force winds into account by either resisting it directly with diagonal bracing, specifying a wall system with SIPs or using conventional framing. In California, seismic forces usually govern so we design for those. Timber Frame Engineering.

What are Ties or Tie Rods and Why do I Need Them in My Timber Frame?

Tie Beams or Tie Rods are used to literally hold the roof up. Our favorite way to demonstrate the need for tie rods is to take a business card and fold it into the shape of a house with a bend in the middle for the peak of the roof and a bend midway down both sides to replicate the intersection of the walls and roof. The next step is to tape the very bottom so the tape represents the bottom floor of the building. Now the fun part: press down on the peak of the roof and watch the walls bow out. The house collapses. Now, if you add a piece of tape at the roof and wall intersection and then press down, the house stays up! that is why tie beams or tie rods are needed – they hold the walls and roof together and add required structure to the building. Wood tie beams are just that – horizontal beams through a building. You can see examples of steel tie rods on our Tension Ties page.

What is Better: Timber Frames Cut on a CNC Machine or Handcrafted Timber Frames?

Of course we believe that cutting frames by hand, the old fashioned way, is better. To us it is more precise and allows us to work with the natural shape and grain of the wood. Many of our client’s can’t believe that we still cut our timber frames using traditional hand and power tools like circular saws, mortising machines, drill stands and good old super sharp chisels. Production timber framing shops are using CNC machines to cut frames these days and it works well for them when they are cookie cutting post and beam frames many similar, simple parts. For whatever reason, Vermont Timber Works has evolved into a very custom shop with unique designs and joinery that don’t lend themselves to mass production, so we do it the time tested way that it has been done for generations. Read about Timber Framing Tools

I Saw a Home on Your Website I like. Can you design and build similar Timber Frame for me?

Yes! It is incredibly helpful when clients come to us with ideas and inspiration for what they want their home to look like, especially when it’s similar to something we’ve already built. We never build the exact timber frame twice, but we will happily customize your design to meet your exact requirements. If another architect or designer designed the home you like we can put you in touch with them to see if they are interested in helping with your design or to see if you can buy plans and the copyright from them.

Do You sell House plans for Post and Beam Homes?

We like to build what we design, so unfortunately, we do not sell plans. Because of how full our workload is, we rarely take on projects that only involve design work. Because everything we do it custom, we don’t have predesigned plans for sale.

Do You sell Timber Frame House Kits?

We sell Timber Packages that include the fabricated timber frame for your house. You can think of the timber frame as a kit, as it is prefabricated and ready to assemble when we ship it to you. We may also sell the decking for the roof and walls and the structural insulated panels (SIPs). We have found that it is more economical for our clients to buy doors, windows, siding, roofing, and general building materials locally, so we don’t supply those items.

Will you Build the Entire House from Start to Finish?

Vermont Timber Works will work through the design and engineering of the Timber Frame, and we will fabricate, deliver and often erect the Timber Frame. You will need to hire a contractor or builder to complete the Home by adding siding, windows, doors, roofing, etc. We are happy to work with the local contractor to provide technical assistance.

I saw a Home Design I liked on another Company's Website. Can you Replicate the Design?

We accept inspiration from everywhere, but we believe that it isn’t ethical to copy another company’s design. While we are happy to incorporate elements from other designs into your custom Timber Frame Home design, we are unable to copy or replicate other company’s designs. A couple of solutions exist; you can contact the owner of the design and ask for permission to use their design (usually for a copyright fee), or we can design a similar, but decidedly different frame for your home.

Can I just buy Steel Brackets/Plates/Tie Rods I see on your Timber Trusses?

We don’t keep any steel plates, brackets or tie rods on hand or “in stock.” Unfortunately, due to our workload, we don’t have the capacity to provide any custom steel fabrication unless we will also be fabricating your Timber Frame as well. If you’re only looking for steel work, contacting a local steel fabricator near you would be a good place to start.

Can I just Hire You to Design and Fabricate Decorative Timber Trusses in one or more rooms of my Home?

Yes. We have worked with clients who wanted only trusses in one room like the Great Room or Dining Room. We can design heavy timber trusses for your home whether they need to be structural or purely decorative. We can also add decorative wood ceiling beams or wall posts to any home, even if it has already been built.