What is Heavy Timber?

Heavy Timber is a construction method that uses large wooden beams to form the framework of a building. The timber beams are both functional and beautiful to see as straight floor beams or as roof trusses. They can either be glue-laminated or solid sawn. Heavy Timber is also a fire rated classification known as Class IV. In Class IV Construction, sprinkler systems are often not needed as long as the timbers are 6″x6″ to 6″x8″or greater in size (specific rules and codes apply). The CSI Specification for Heavy Timber is 06130, for Heavy Timber Framing it is 061323 and for Heavy Timber Trusses the spec is 061326. Vermont Timber Works is the leader in heavy timber construction because our commercial clients know that we offer a truly exceptional product, outstanding customer service, and relentless attention to detail. We have 30 Years of experience and offer competitive bids, with delivery and installation available nationwide.

Architectural

Specification 06130

Since 1987, we have been a specialized heavy timber supplier of commercial timber frames. We have a hard-earned reputation for being hands-on and collaborative.

The Process

Whether your project calls for natural timbers or glue-laminated timbers, we design, engineer, fabricate and install custom heavy timber frames, down to the last hardwood peg, hammered in by hand. Our commercial clients appreciate that we fabricate traditional wood joinery as well as metal plate connections for our Class IV heavy timber buildings, as each is often vital to ensuring both structural integrity and the warm beauty that only a wood timber frame can create. If you need a heavy timber contractor, Vermont Timber Works is your best choice.

Whether you have architectural drawings, plans or just have an idea, we want you to bring everything you have to the table so that our designers and engineers can better understand the style, function, and design of your commercial Heavy Timber Frame.

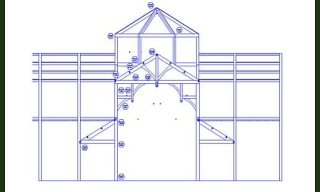

Once a design has been created, you will be able to review a 3D, rotating computer generated model prior to fabrication to see exactly how your Heavy Timber Frame will look, including the location of all posts, beams, and braces. All our frames are checked by our in-house structural engineer for strength and integrity.

Raw beams are sent to us from the sawmill. The parts are selected and are laid out and cut by hand. The joints are cut, the peg holes are drilled and each timber is individually marked according to its exact location in the frame. After being cut to size and specification, all the timbers are cleaned and prepared for finishing. Then a stain or urethane of your choice is applied.

All timber frames are different, but the steps to assemble and raise any post and beam frame or timber frame are similar. First the column locations are laid out. Anchor rods are often drilled and epoxied into the foundation. The bents are pre-assembled on the ground, and a crane lifts the assembled parts into place. Either our crew or an experienced site crew can do the job.

Heavy Timber Categories

With widely recognized companies and organizations on our client list including the Trapp Family Lodge, Southeastern Vermont Welcome Center, Jay Peak Ski Resort and the Billings Farm and Museum, Vermont Timber Works enjoys a varied and rich Heavy Timber Framing Portfolio.